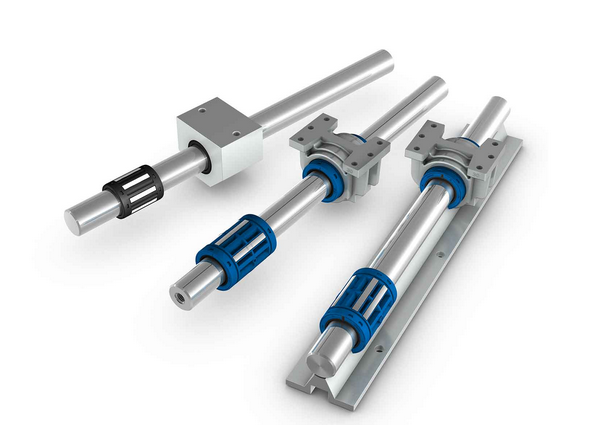

In today’s modern industrial world, precision and efficiency are key factors in supporting productivity. One of the essential components in linear motion systems, commonly used across various machine applications, is the linear bearing. Despite its relatively small size, it plays a crucial role in ensuring smooth, stable, and low-friction movement of machine components.

A linear bearing is a type of bearing specifically designed to support linear or unidirectional motion. Unlike conventional bearings that facilitate rotational movement, linear bearings allow shafts or components to move back and forth precisely along a designated path.

These bearings are widely used in automation systems, CNC machines, industrial printers, precision measuring instruments, and even medical equipment due to their ability to support accurate and low-friction motion.

Here are the key functions of linear bearings in mechanical systems:

1.

Facilitates Precise Linear Movement

Linear bearings ensure that components

move smoothly and straight without obstruction, making them ideal for machines

that require stable and accurate motion.

2. Reduces Friction

Using rolling elements such as balls or

rollers, linear bearings reduce friction between moving surfaces. This helps

minimize wear and extends the lifespan of machine components.

3.

Efficient Load Support

Depending on their type and design,

linear bearings can support both radial and axial loads, enabling machines to

maintain optimal performance even under heavy-duty conditions.

4. Improves Energy Efficiency

Lower friction means less force is

required to move components. This leads to energy savings and more efficient

machine operation.

5.

Minimizes Vibration and Noise

High-quality linear bearings help

dampen vibrations and noise during motion, making them ideal for high-precision

applications.

To meet diverse industrial needs, several types of linear bearings are available, including:

Linear bearings are widely used across

various industrial sectors, including:

To ensure optimal machine performance,

it is important to choose the right linear bearing. Consider the following

factors:

If you’re unsure, consult with SLS Bearings , a trusted provider of mechanical components, to ensure you select the most suitable linear bearing for your industrial application.

Linear bearings are an ideal solution for enabling precise, efficient, and durable linear motion. By understanding their functions and applications, you can optimize the performance of your machines and overall industrial production systems. Be sure to choose high-quality linear bearing products that match your needs to get the best long-term return on your investment.

Contact Us

Contact Us