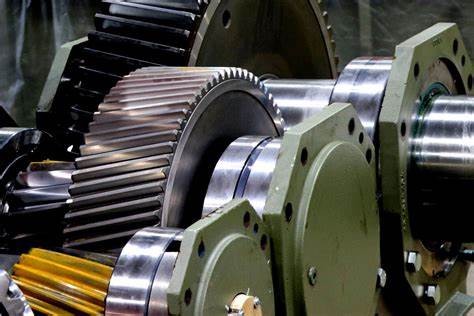

In industrial operations, gearboxes

are critical components that keep machinery running smoothly. Gearboxes are

essential for transferring power from motors to machinery, ensuring that

everything from conveyors to crushers functions effectively. However, like any

mechanical component, gearboxes are subject to wear and tear over time. Without

regular gearbox services and repair, you could face costly downtime,

unexpected failures, and reduced productivity.

In this blog, we’ll discuss why gearbox

maintenance is essential, the types of services available, and how regular

repairs can extend the life of your equipment, reduce costs, and improve your

overall operational efficiency.

1. The Importance of Regular Gearbox

Maintenance

Gearboxes operate under heavy loads, high

speeds, and varying environmental conditions, which can cause them to wear down

over time. A well-maintained gearbox operates more efficiently, improves the

performance of the machine, and reduces energy consumption.

Regular gearbox maintenance helps identify potential issues before they lead to catastrophic

failure, preventing costly breakdowns and repairs. Some of the benefits of

regular maintenance include:

- Increased Equipment Lifespan:

Proper maintenance ensures that your gearbox lasts longer, reducing the

frequency of replacements.

- Enhanced Efficiency: A

well-maintained gearbox runs more smoothly, which contributes to improved

operational efficiency and reduced energy consumption.

- Reduced Downtime: Identifying and

repairing problems early prevents unexpected failures that can halt

production.

2. Common Gearbox Problems and Signs You

Need Repair

Gearboxes often show signs of distress

before they fail completely. By recognizing these signs, you can take action

before issues escalate, avoiding costly repairs or replacements.

Some common gearbox problems include:

- Excessive Noise: Unusual grinding,

whining, or clunking sounds can indicate worn-out gears or bearings.

- Overheating: If the gearbox

temperature rises too high, it can result in oil breakdown, which may

cause damage to internal components.

- Vibration: Excessive vibration can

be caused by misalignment, imbalance, or worn components within the

gearbox.

- Oil Leaks: Leaking oil is a sign

that seals may be damaged or worn, which can lead to a loss of lubrication

and cause further damage.

- Loss of Power: A noticeable

reduction in performance or power output may indicate internal damage.

If you notice any of these issues, it’s

essential to schedule a gearbox repair service immediately to prevent further

damage.

3. Types of Gearbox Services Offered

Gearbox service providers typically offer a

wide range of services to ensure your gearboxes are operating at peak performance.

Some of the most common services include:- Inspection and Diagnostics: A

thorough inspection of the gearbox to identify any wear, misalignment, or

potential issues. This includes checking the oil levels, gears, bearings,

and seals.

- Oil and Lubricant Replacement:

Regular oil changes help maintain proper lubrication, which is essential

for preventing wear and tear on gearbox components.

- Alignment and Balancing:

Misalignment can cause unnecessary stress on the gearbox, leading to

premature wear. Alignment ensures the gears are properly set, while

balancing helps reduce vibrations.

- Component Replacement: If worn-out

parts such as bearings, seals, or gears are identified, they are replaced

with high-quality components to restore gearbox functionality.

- Rebuilding and Overhaul: In cases

of severe damage or wear, a complete rebuild or overhaul may be necessary

to restore the gearbox to its original condition. This may involve

cleaning, inspecting, and replacing internal components.

4. The Gearbox Repair Process: What to

Expect

When you send your gearbox for repair, the

process typically involves several key steps:

- Initial Inspection: A team of

experts will thoroughly inspect the gearbox to identify the extent of the

damage and the root cause of the problem.

- Diagnosis: After inspection,

technicians diagnose the issue and recommend the necessary repairs or

replacements.

- Disassembly and Cleaning: The

gearbox is disassembled, and internal components are cleaned to remove

debris, dirt, and old lubricants.

- Component Repair/Replacement:

Worn-out components, such as bearings, seals, or gears, are repaired or

replaced with new ones.

- Reassembly and Testing: After

repairs, the gearbox is reassembled, and thorough testing is done to

ensure it functions properly before being returned to the customer.

- Post-Service Inspection: A final

inspection ensures that everything is working correctly, and that the

gearbox meets operational standards.

5. Choosing the Right Gearbox Repair

Provider

When selecting a gearbox repair service,

it’s important to choose a provider with expertise in your industry and

experience working with the type of gearbox you use. Look for these key

factors:

- Expert Technicians: Ensure the

service provider employs certified technicians who are skilled in gearbox

repair and have a deep understanding of your industry’s needs.

- Quality Parts and Components: A

reliable repair provider will use high-quality, OEM (Original Equipment

Manufacturer) parts to replace damaged components.

- Comprehensive Services: The provider

should offer a range of services, from routine maintenance to complex

repairs, to address all potential gearbox issues.

- Quick Turnaround Time: Downtime is

costly, so choose a provider who can complete repairs efficiently without

compromising on quality.

- Customer Support and Warranty: A

strong customer support team and warranty options demonstrate the

provider’s commitment to customer satisfaction.

6. How Regular Gearbox Services Save You

Money

While gearbox repairs may seem like an

added cost, investing in regular maintenance and timely repairs can save you

significant amounts in the long run. Here’s how:

- Prevention of Major Failures: Early

detection of issues can prevent more serious problems that would require

costly repairs or replacements.

- Increased Energy Efficiency: A

well-maintained gearbox operates more efficiently, which reduces energy

consumption and lowers operational costs.

- Fewer Unexpected Downtimes: With

regular maintenance, you reduce the likelihood of unexpected breakdowns,

ensuring that your machinery runs smoothly without interruptions.

- Longer Equipment Lifespan:

Extending the life of your gearbox delays the need for a costly

replacement, providing better value over time.

Conclusion: Keep Your Gearboxes in Top

Condition for Long-Term Success

Regular gearbox maintenance and repair

are essential for ensuring your machinery continues to operate efficiently and

reliably. By investing in regular maintenance, addressing issues early, and

choosing the right repair provider, you can extend the life of your equipment,

reduce unexpected downtime, and save money in the long run.

If your gearbox needs maintenance or

repair, don’t wait until it’s too late. Contact us today to schedule an

inspection or request a quote for repair services. Our expert technicians are

here to ensure your equipment stays running smoothly and your operations stay

productive.

Need reliable and expert gearbox repair

service? Please contact us today for a free consultation or to book your next

gearbox service. Let us help you keep your machinery in optimal condition and

prevent costly downtime.

Contact Us

Contact Us