Electric motors are the heart of manyindustrial applications, powering everything from conveyors to crushers, pumps,and fans. Like any mechanical system, electric motors are subject to wear andtear over time. Proper maintenance is essential to ensuring that these motorscontinue to operate at peak performance, reducing downtime, and extending theirlifespan.

In this blog, we’ll share essentialelectric motor maintenance tips to help you maximize the performanceof your motors and avoid costly repairs or replacements. By following thesemaintenance practices, you can improve reliability, efficiency, and productivityin your operations.

1. Regular Inspections: Catch IssuesEarly

A proactive approach to maintenance beginswith regular inspections. A detailed inspection can help identifypotential problems before they lead to motor failure. Look out for thefollowing signs during routine checks:

Pro Tip:Schedule inspections regularly—quarterly or annually depending on the motor’soperational conditions and criticality.

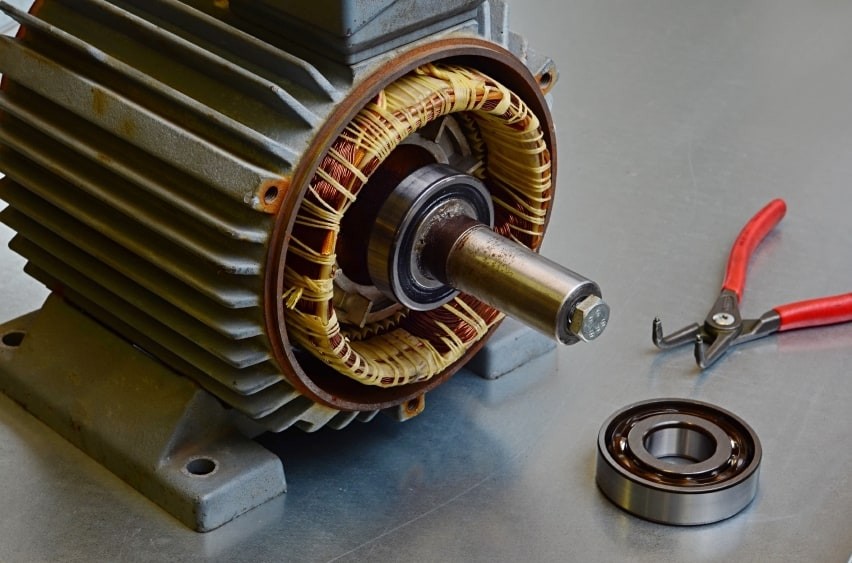

2. Lubrication: The Lifeblood of Bearings

Bearings are a crucial component inelectric motors, allowing smooth rotation and reducing friction. Properlubrication of motor bearings is essential to reduce wear and tear, minimizenoise, and ensure longevity.

Pro Tip:Over-greasing can lead to overheating and increased friction. Apply only therecommended amount of grease.

3. Monitor Temperature and Vibration

Excessive heat or vibration are commonindicators of motor problems. Monitoring these conditions can help you identifyissues early and take corrective action.

Pro Tip:Implement condition-based monitoring systems to track temperature andvibration in real-time. This allows for predictive maintenance and moreefficient troubleshooting.

4. Check Electrical Connections

Electrical connections are vital for propermotor function. Loose or corroded connections can lead to power loss,overheating, or even failure.

Pro Tip:Always turn off the motor and disconnect power before performing any electricalchecks or repairs.

5. Alignment and Shaft Balancing

Misalignment of the motor shaft can lead tovibration, bearing failure, and excessive wear. Proper alignment of the motorand driven equipment is essential for smooth operation and minimizing downtime.

Pro Tip: Uselaser alignment tools for more precise shaft alignment and to avoid costlymisalignment-related issues.

6. Keep the Motor’s Environment Optimal

The environment in which the electric motoroperates plays a huge role in its longevity. Factors like temperature,humidity, dust, and ventilation all affect motor performance.

Pro Tip: Formotors in outdoor or harsh environments, invest in weatherproof orexplosion-proof motor housings to protect against external damage.

7. Regularly Test Motor Performance

Motor performance testing is a key step inmaintaining operational efficiency and identifying issues early. Key testsinclude:

Pro Tip:Implement routine performance testing to monitor trends in motor performance.This can help you anticipate failures before they occur.

Proactive Maintenance forMaximized Efficiency

Electric motor maintenance is critical forensuring the reliability, efficiency, and longevity of your machinery. By following the tips outlined above, you can significantly reduce downtime,increase the lifespan of your motors, and improve operational efficiency.

Proactive care and regular inspections cansave your business from costly repairs and unplanned shutdowns, allowing yourequipment to operate at its best for years to come.

If you need assistance with electric motormaintenance or repairs, contact us today. Our team of experts is ready to helpensure your motors are running smoothly, efficiently, and reliably.

Want to ensure your electric motors are intop shape? Contact us for a professional motor maintenance consultation orschedule an inspection with our experienced technicians.

Бидэнтэй холбогдох

Бидэнтэй холбогдох