Electromechanical actuators and pillars perform vital motion and positioning roles in hospitals, diagnostic centers, and outpatient healthcare facilities. They are integrated into surgical tables, medical procedure chairs, and similar end-use equipment requiring controlled, safe, and repeatable patient positioning. They are commonly specified for their load capacity to perform push or pull movements, vertical lifting, and/or patient tilting functions.

But what parameters should designers especially consider when specifying these actuator systems for such critical applications?

Designers will want to evaluate the load capacity (achieving necessary support throughout operation), entry heights (associated with patient access), safety and regulatory requirements, the extent of play of the drive system (affecting equipment stability), speeds (influencing treatment time and productivity), and noise (quieter is better both for patient and operator). Beyond these parameters, issues such as the available footprint for system integration, anticipated maintenance requirements, and sophistication and versatility of control units and accessories will also come into play.

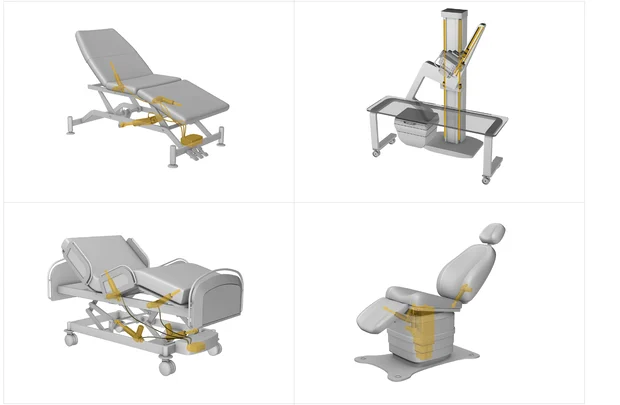

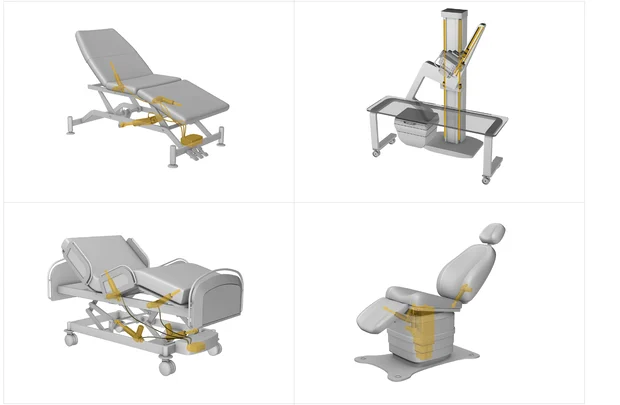

Linear actuators and telescopic pillars can be found in various applications in the healthcare industry such as stretchers (top left), X-ray patient tables (top right), intensive care beds (bottom left), and procedure patient chairs (bottom right)

Anatomy of Actuators and Telescopic Pillars

A linear actuator is a system consisting of an electric motor and a mechanical mechanism to translate rotational to linear movement. Primary components include the electric motor, gears, and a screw drive. By applying power to the motor, the actuator pushes or pulls a load.

An example of Ewellix Linear Actuator

A telescopic pillar is essentially an actuator housed inside a guided tube-set acting as a stability element to guide actuator movement. A telescopic pillar typically will be used to mount a table or chair platform and lift and lower the equipment as needed. While pillars can lift the same loads as actuators, their guiding functionality inherent in the profile tubes enables them to accommodate offset and moment loads without the need to design an additional support and guiding frame.

An example of Ewellix Telescopic Pillar

Some pillars are multi-stage enabling vertical movement in two or more stages. While a single-stage pillar has one screw that pushes two tubes apart to lift a load, a double-stage pillar has a double acting mechanism (with two screws) that pushes three separate stages apart (one stage pushes against the second and the second pushes against the third).

Telescopic pillars are able to achieve a high stroke to retracted height ratio, which is particularly relevant for surgical tables and procedure chairs. This ratio allows a table or chair to be positioned very low (easier access for patients) and travel very high (ergonomic benefits for medical staff). Entry height capabilities have become a matter of regulation – evidenced by the Americans with Disabilities Act (ADA) requiring equipment with an entry height of 17-19 inches.

Scissor mechanisms can also be used for patient lifting functions, especially in procedure chairs. Advantages include a low retracted height with high stroke, but the downside is poor stiffness characteristics, and a much more complex chair design with high number of parts and added assembly time and cost. For surgical tables requiring a small footprint of the central frame, a scissor mechanism with a corresponding load and stiffness is simply too large to be a viable option. In contrast, pillars can be supplied as “plug-and-play” systems without the issues associated with complex assembly, performance, and size limitations.

Competing with electromechanical actuator and pillar technologies, hydraulic systems are often used to perform positioning functions. While hydraulic systems, in general, are compact and provide high power density relative to their size, several disadvantages make them a less favorable option for new developments. Poor positioning capability, slow speeds, high service requirements, and the ever-present risk of oil leakage have largely relegated hydraulic systems to the second choice behind electromechanics.

Checklist for Optimized System Design

Optimized patient positioning systems will rely upon a designer’s insights into the performance and safety needs of an application and how potential issues can be resolved at the outset. Here's a checklist of basic objectives to help guide the decision-making process:

1. Ascertain Load Requirements

Electromechanical actuators and pillars for chairs and tables must be able to support imposed patient loads and load capacities will vary, depending on the required function. For example, when designing a procedure chair to handle up to 600 lb. patients, the load capacity of the actuators can vary between 2000 N for leg adjustments and up to 6000-8000 N for back adjustment and Trendelenburg (longitudinal tilting of the body axis).

An important factor to consider when designing the lifting function with a telescopic pillar is the distance of the center of gravity in relation to the center of the pillar, since the offset load introduced by this can introduce a significant additional load. A pillar load capacity of 4000 N is generally sufficient to handle a 600 lb. patient, while 6000 N would be more suitable for patient loads up to 1000 lbs.

2. Safety First

The mechanical and electrical safety of the equipment is a key requirement that should not be taken lightly. Depending on the chair or table, a first failure safety factor of 2.5 to 4 times maximum load (up to which there can be no collapse to harm the patient) has to be implemented. Actuators and pillars certified according to the medical safety norm IEC 60601-1 should be chosen to reduce the risk to the patient and reduce final system certification time.

3. Minimize System “Play.”

Overall system stiffness and low play design can be a key requirement when designing tables and chairs for critical procedures, such as eye surgery. Play can be introduced from the actuator (overall construction, screw design, brakes, and/or gears), as well as from attachment points and hinges. Additionally, equipment stiffness can be affected, resulting in uncontrolled shaking or wobbling. All these adverse actions can be minimized by introducing smart designs and choosing a play reduced actuator design. As an example, an actuator play of only 0.5 mm can result in play of up to 5 mm at the end of the table, depending on the levers evident in the equipment.

4. Confirm Speed Ranges

Lifting speeds of procedure chairs and surgical tables should not be too slow to reduce treatment time. Speeds for pillars in procedure chairs typically can reach up to 35 mm/s, while speeds for operating tables can be slower at 15 mm/s. Speeds for actuators involved in functions other than lifting can be as slow as 5mm/s to 10mm/s, since these usually are designed to perform a turning function by pushing a short lever.

5. Reduce Noise Levels

The noise level of electromechanical actuators is generated by a combination of the electric motor, gear, and screw design. Designers can reduce noise by specifying actuators with slower-turning (low-noise) motors and worm gears and by introducing noise-damping covers, among other measures.

Taking Control

Technology advances in actuators and pillars have extended to their control units, which have continued to evolve in terms of functionality and connectivity for patient positioning applications.

Controllers can be configured to manage multiple actuators and pillars and, integrating microprocessors, specifically can manage position control, speed, synchronized movement, dependency between actuators, and safety stops, among other functions. Input devices (hand switches, foot switches, and wireless switches), external limit switches, and other safety elements can also be managed using appropriately specified control units.

Controllers further can be equipped to recall memory positions, allowing for quick setup of frequently required setups, such as a “home” for returning a table back to a basic starting point for the next patient.

On the horizon, innovations in the world of electromechanical actuators and pillars promise to elevate functionality, performance, and reliability. These include increased connectivity capabilities, condition monitoring to assess the health of the systems for timely service calls, and wireless input via smartphones, among many other developments.

As with the mechanical system components, medical controllers should be certified according to IEC 60601-1 to ensure maximum electrical safety for the patient and operator and to reduce development time and risk for OEMs.

Where to Begin?

OEM designers can get a big assist – reduced risk and faster time to market – by considering complete actuation systems in which all components have been tested and validated together and UL certified in accordance with IEC 60601-1 medical safety standards. Partnering early in the design stage with an experienced manufacturer ultimately can help keep any actuation application moving in the right direction.

Interested to know more about Electromechanical Actuators and Pillars?

Regardless of the industry you're in, we are here to help you find the right type of linear motion solutions when it comes to your actuator and pillar needs. If you would like to learn more, please get in touch with us below:

Ewellix is a global innovator and manufacturer of Linear Motion and Actuation solutions used in industrial automation, medical applications, mobile machinery and distribution. Formerly part of SKF Group, the Ewellix Group consists of 16 sales units and nine factories. External net sales are approximately 2.3 SEK billion and we employ around 1400 people. Ewellix is headquartered in Gothenburg, Sweden and is owned by Triton Partners.

**All images were derived from Ewellix

Contact Us

Contact Us