In the marine and shipyard industry, every machine operates under intense and unforgiving conditions. From cranes and pumps to propulsion systems and conveyors, equipment are constantly exposed to saltwater, humidity, vibration, and heavy loads. Over time, these factors accelerate corrosion, misalignment, and mechanical wear, which can lead to reduced efficiency, equipment failure, and unplanned downtime.

When even one critical component fails, it can disrupt production schedules, increase safety risks, and incur costly delays. That’s why more shipyards are turning to predictive maintenance, which is a data-driven, proactive approach that ensures equipment reliability, reduces machine downtime and extends operational life in the harshest marine environments.

Challenges in Marine and Shipyard Equipment Maintenance

Few industries test machinery as harshly as the marine sector. Constant moisture, high humidity, and mechanical vibration place enormous stress on even the most durable components.

Common challenges include:

- Corrosion: Exposure to saltwater and marine air accelerates metal corrosion and rust.

- Misalignment: Shaft or coupling misalignment causes vibration, power loss, and premature wear and tear on bearings.

- Mechanical wear: Continuous heavy-duty operation accelerates fatigue and surface damage.

- Unplanned downtime: Equipment failure leads to production halts, schedule disruption, and safety risks.

What is Predictive Maintenance and Why It Matters for Marine Operations

Predictive maintenance represents a major advancement over traditional reactive maintenance methods. Instead of relying on fixed schedules or reacting to failures, it utilises real-time analytics and data to predict when equipment issues are likely to occur, enabling timely intervention by tackling the root cause and implementing maintenance activities before damage escalates.

This data-driven maintenance strategy enables shipyards to:

- Track equipment health through sensor data and vibration analysis.

- Reduce unnecessary maintenance tasks.

- Prevent unplanned downtime and equipment failures.

- Improve safety and overall operational efficiency.

Predictive Maintenance Solutions by SLS Bearings

At SLS Bearings, we understand the unique maintenance challenges faced by the marine and shipyard industry. Our predictive maintenance services are designed to enhance reliability, efficiency, and safety in high-demand operations.

Laser Alignment Services

Accurate alignment is a critical part of machine health. Laser alignment services correct shaft and coupling misalignment, reducing vibration, preventing premature wear, and extending the life of electric motors, bearings, seals, and other equipment.

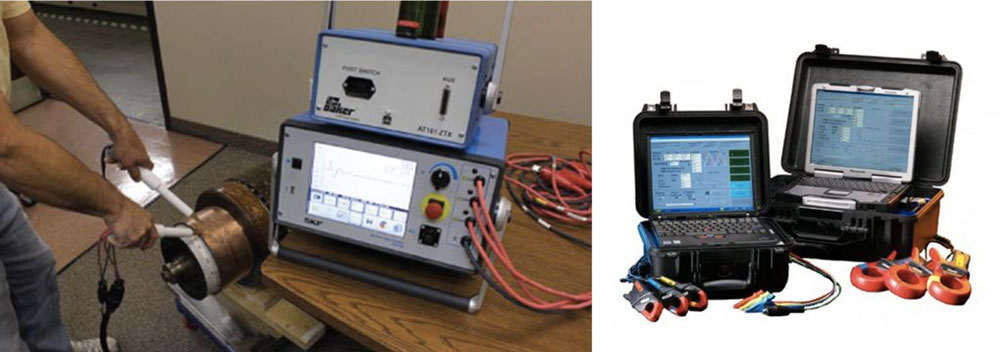

Dynamic Balancing and Vibration Analysis

Unbalanced rotating parts create excessive vibration and stress on motors, couplings, and bearings. SLS Bearings provides dynamic balancing and vibration diagnostics to detect imbalance, looseness, or bearing defects early. This ensures smooth and energy-efficient operations.

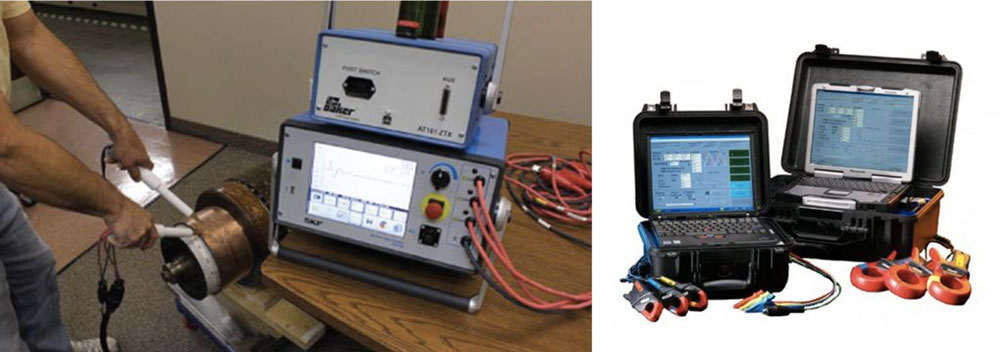

Thermography and Ultrasonic Testing

Our thermography inspection and ultrasonic testing services detect abnormal heat, friction, or lubrication issues, all of which are the early indicators of wear and failure. By addressing these problems proactively, maintenance teams can prevent costly breakdowns and improve reliability.

Key Benefits of Implementing Predictive Maintenance For the Marine Industry

Predictive maintenance delivers measurable improvements in both operational and financial performance. Some key benefits of implementing predictive maintenance include:

Reduced Machine Downtime

Identifying potential failures in advance allows maintenance teams to take preventive action before equipment failure occurs, reducing unplanned downtime and ensuring continuous operation.

Lower Maintenance Costs

Identifying potential failures in advance allows maintenance teams to take preventive action before equipment failure occurs, reducing unplanned downtime and ensuring continuous operation.

Extended Equipment Lifespan

By maintaining optimal alignment, balance, and lubrication, machinery and equipment will experience less stress, reducing wear and replacement costs.

Lower Maintenance Costs

Predictive maintenance focuses on actual equipment needs rather than adhering to fixed schedules, optimising resources while reducing unnecessary maintenance costs and service interventions.

Improved Energy Efficiency

Well-aligned and balanced systems consume less energy, improving overall sustainability and performance.

Enhanced Safety

Regular monitoring reduces the risk of sudden equipment failures and ensures safer working environments in shipyards and offshore operations.

The Future of Predictive Maintenance: Robotics, Machine Learning, and Automation

As the marine industry embraces digital transformation, new developments like robotic automation, machine learning, and AI-driven inspection are redefining how maintenance is performed.

Automated systems equipped with sensors, cameras, and artificial intelligence can make use of real-time data to perform alignment, vibration monitoring, and corrosion inspection in confined or hazardous areas. This improves precision and safety while reducing human exposure.

Advantages of Robotics, Machine Learning, and AI-Based Predictive Maintenance Systems

Continuous, high-accuracy monitoring for reliable diagnostics.

Real-time data analysis and automated reporting.

Enhanced predictive intelligence for proactive maintenance planning.

Reduced operational risk in offshore and shipyard environments.

By integrating robotic systems into predictive maintenance workflows, shipyards can move toward automated, self-diagnosing operations that improve reliability, reduce costs, and support long-term sustainability goals.

Building Smarter, Safer, and More Reliable Shipyard Operations

Ready to strengthen your marine and shipyard operations? Discover how SLS Bearings can help you improve reliability, reduce machine downtime, and protect critical assets from corrosion and misalignment.

Visit our

Marine & Shipyards Industry page or

contact our SLS PRO team today for tailored predictive maintenance solutions.

Contact Us

Contact Us