Products & Services Industry Guides

Roller bearings are fundamental components in machinery and engineering that facilitate smooth and efficient motion in various applications. These precision-engineered mechanical elements are designed to reduce friction with their rolling elements and support high radial, and axial loads for heavy-duty applications.

Unlike traditional sliding bearings, roller bearings are cylindrical and have a design that minimises friction and heat generation. This design also assists in distributing loads evenly, resulting in improved mechanical efficiency and durability.

Despite its cylindrical design features, it should not be confused with cylindrical roller bearings which are designed for high-speed applications. Instead, roller bearings are best suited for high-load capacity, low-speed applications.

Roller bearings find extensive use in industries such as automotive, aerospace, manufacturing, and construction. This is made possible by the cylinder rolling elements in the bearings which enable a smoother wheel rotation, shafts, and other critical components relevant to said industries. Their versatility and reliability have made them a cornerstone in modern engineering, whether in a vehicle's wheels, an aircraft's turbines, or in factory machinery.

Roller bearings like any mechanical part, are susceptible to common problems that can compromise their performance and longevity. In the following points, we will delve into the frequent and common challenges associated with roller bearings, which include bearings noise and vibrations, premature failure, lubrication, and contamination issues.

Since roller bearings are utilised to support high radial and axial load, noise and vibration problems in roller bearings are very common because of improper procedures or other underlying problems. This can negatively impact the performance and longevity of the machinery it operates within.

The primary noise source in roller bearings is the interaction between cylinder rolling elements (e.g. rollers, balls), the cage, and the bearings raceways. Excessive noise can indicate wear and friction and may aggravate the issue by causing bigger damage to the bearings and machinery it operates if not addressed promptly. Additionally, the resulting noise is disruptive to the work environment.

The vibration of roller bearings arises from the dynamic forces generated during operation that cause the rolling elements to move within the bearings. Vibration can result from misalignment, unbalanced loads, or contaminants. High vibration levels can also adversely affect the surrounding machinery, reducing its efficiency and causing damage.

Premature failure in roller bearings refers to unexpected breakdowns before their anticipated lifespan. Issues arise from numerous factors originating from either the rolling bearings itself or the machinery it was placed in.

The primary source of premature failure in roller bearings is the excessive stress and wear placed on the bearing components during operation especially the components that enable the bearings to rotate. This will lead to abrasion and surface wear can occur between inner rings and outer rings, rolling elements, raceway, and contaminants, resulting in frequent replacement and increased maintenance costs.

Lubrication is important to ensure optimal bearing performance, extend lifespan, and prevent costly equipment downtime and repairs. While it is a routine maintenance procedure, its application demands precision and suitable care as incorrect application can damage the machine severely.

For example, insufficient lubrication will cause friction between components to increase and it does not solely occur to roller bearings, under-lubrication can happen to linear bearings as well. This might also lead to inadequate protection and increased wear, especially around the rolling elements area. With increased wear and more friction, and raceways will generate more heat, leading to heat build-up, and reduced efficiency of the overall performance of the equipment.

Roller bearings issues can arise due to several factors, affecting both performance and workplace comfort. Here are some troubleshooting tips to solve the issues.

A few steps in reducing noise in roller bearings include lubrication management. Ensuring proper lubrication on top of using the right type of lubricant is efficient to help lessen the noise. In addition, noise-dampening solutions are available for most types of roller bearings, including needle roller bearings, spherical roller bearings and cylindrical roller bearings.

Selecting appropriate lubricant can be done based on factors such as your load capacity, speed, temperature, and environmental conditions which you can configure through the manufacturers' guidelines. It helps to establish a schedule to ensure your machine is lubricated at appropriate intervals too.

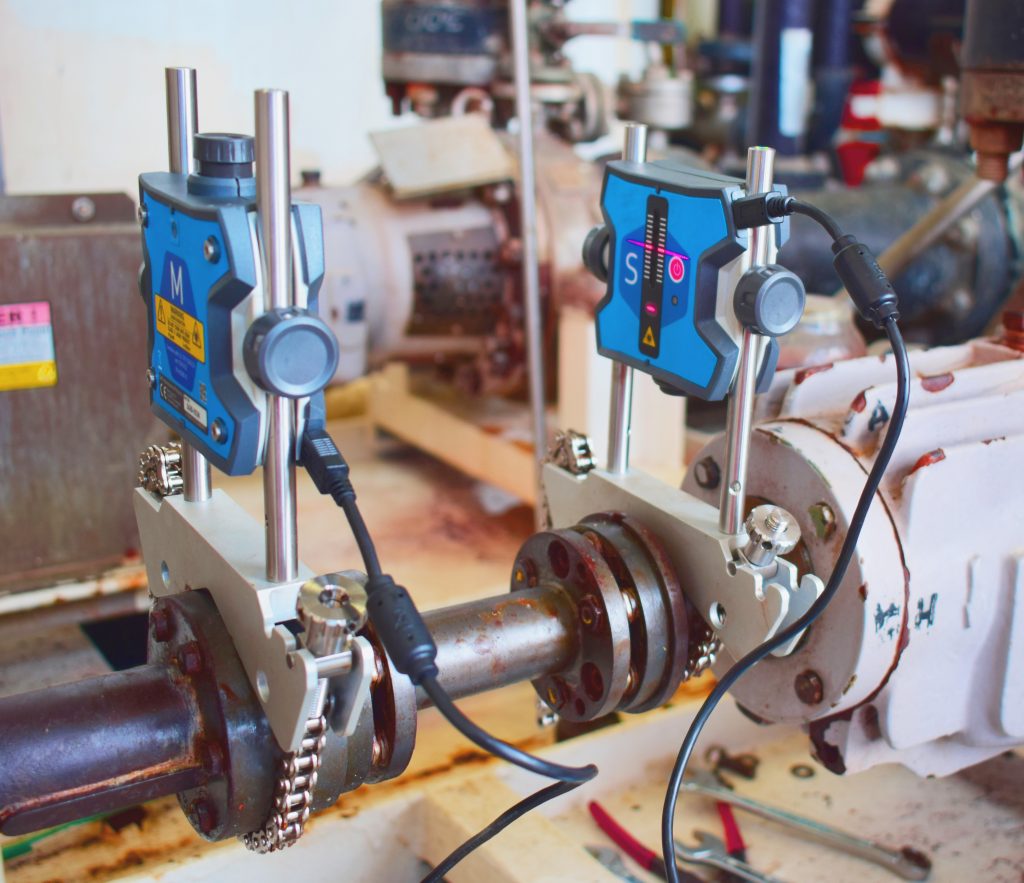

Vibrations can mean there are loose moving parts in your machines that can lead to premature failures. Ensure they are properly tightened by referring to the manufacturer's specifications. In addition, using shaft alignment tools will further prevent this issue by ensuring all your parts have been measured and aligned.

SLS Bearings provides professional shaft alignment services which help to measure misalignment and position your machine parts to fit into your applications correctly.

Vibration analysis is a predictive maintenance solution offered through SLS Bearings that is useful in avoiding premature failure by identifying the root cause of other bearings-related issues as well. These solutions use a variety of sensors (Wired/Wireless Vibration Sensor, Cloud/Local based) that aim at minimising your downtime and optimise resources.

Additionally, regular scheduled maintenance is a must-have practice to avoid unwanted failures and breakdowns too.

To ensure the long-term reliability and performance of your inner and outer rings, roller balls and cylindrical rollers amongst others, here's a breakdown of some maintenance and installation practices for you.

Precise Mounting and Alignment: Use mounting and shaft alignment tools and methods recommended by the bearing manufacturer.

Lubrication and Sealing: Apply the correct lubricant type on the components, especially on the inner ring and outer ring and quantity as per manufacturer guidelines. To reduce friction, you must verify that seals and shields are in place and functioning properly.

Regular Lubrication: Make and implement a lubrication schedule to replenish or replace it when it's needed. Since there are various sizes of roller bearings, you can consult recommendations from the manufacturer for appropriate intervals and amount of lubrication.

Inspection and Vibration Analysis: Conduct routine visual inspections to check for signs of wear, overheating, or misalignment. Use vibration analysis tools to detect early signs of bearing problems. and solve it promptly.

Temperature Monitoring: Continuously monitor the bearing's operating temperature to detect sudden temperature rises. Proper ventilation is also needed to help cool the steel roller bearings.

Here's several key practices that can be implemented to expand your roller bearings lifespan

Sealing and Shielding: Maintain effective sealing and shielding mechanisms to prevent contaminants from entering the bearing. Areas such as the rolling elements, inner and outer rings, double rows and mostly any moving parts also have to be checked regularly.

Monitoring and Maintenance: Implement a robust monitoring and maintenance schedule, including regular visual inspections and vibration analysis to identify early signs of wear, misalignment, or other issues.

Training and Expertise: Invest in training for maintenance personnel aligning with bearing manufacturers' guidelines. An informed team is more likely to follow best practices and identify issues before they escalate.

Addressing common issues with roller bearings is paramount for the smooth operation and longevity of machinery. Understanding the root causes of problems such as noise, vibrations, and premature failure is the first step towards effective troubleshooting.

After all, preventing common roller bearing issues is not just about reducing downtime and maintenance costs; it is about safeguarding the overall performance and efficiency of critical machinery, ensuring a smooth and uninterrupted workflow.

At SLS Bearings, our decades of experience have enabled our deep understanding of the unique challenges faced by our customers. Our quality products offer the best solutions for your roller bearing needs.

Contact us to get a dedicated professional to help you achieve engineering efficiency today!

Essential components ensure smooth and efficient rotational motion in machinery.

Find Out MoreEssential components ensure smooth and efficient rotational motion in machinery.

Find Out More

Contact Us

Contact Us