Products & Services Industry Guides

Industrial hydraulic jacks are deemed the most necessary and invaluable tools. One of the key features of hydraulic jacks is their lifting capacity. Hydraulic jacks, such as the hydraulic bottle jack, are versatile lifting devices that can be found in various industries. They can lift or lower anything from patient beds to large trucks by employing the principles of fluid dynamics. This article explores how hydraulic jacks operate, the different types available, their industrial application, and the benefits they offer.

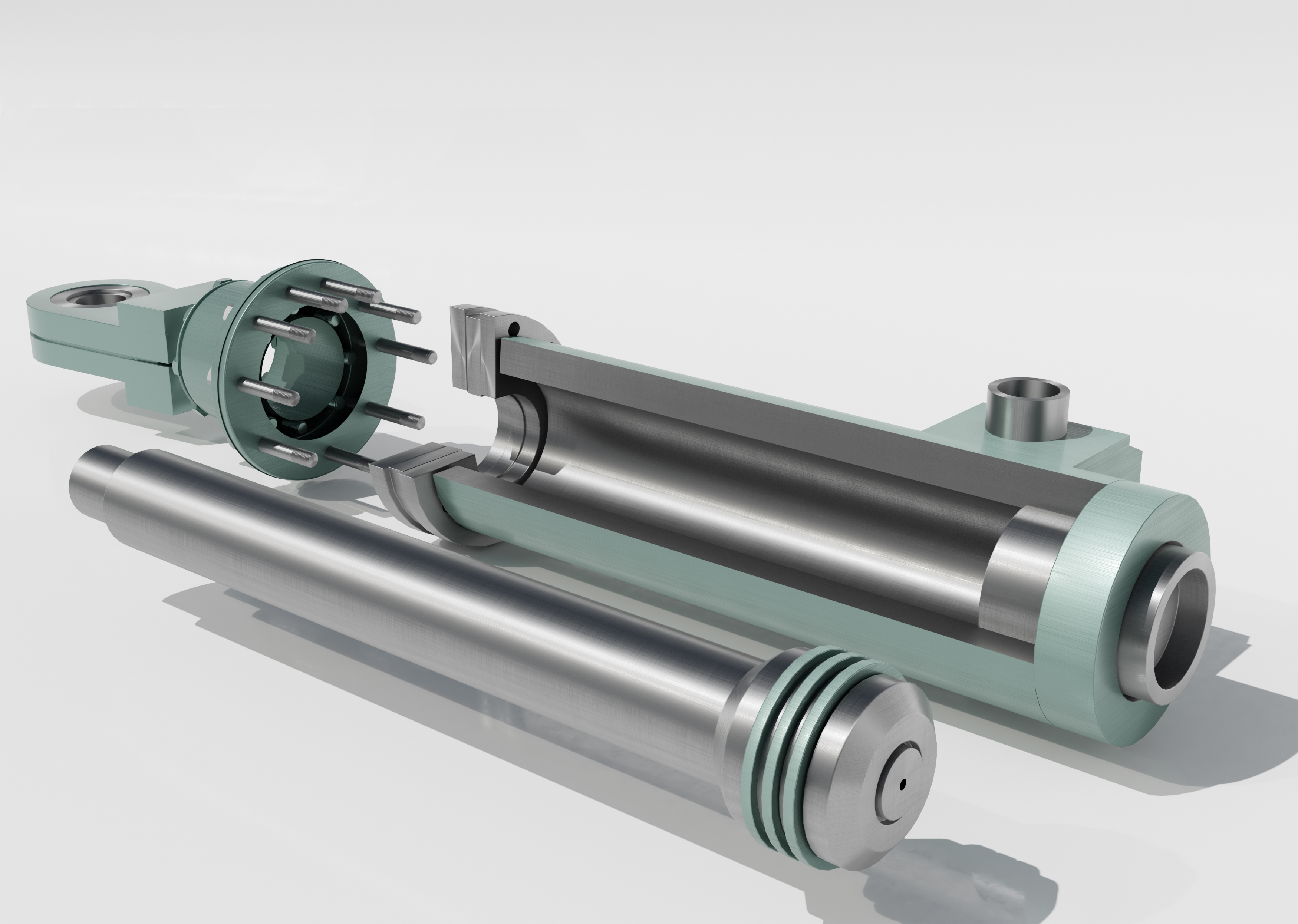

Pascal’s Law states that an incompressible fluid will distribute pressure uniformly throughout the fluid when pressure is added, and is the foundation upon which hydraulic jacks function. Here’s a fundamental breakdown of the seven primary hydraulic jack parts and its operation:

Mechanism: When the jack is in use, the hydraulic system within it transmits that force to a larger contained space filled with fluid. The larger quantity of fluid multiplies the force that was originally applied by the operator. This results in the operator lifting something much heavier than they could single-handedly. The performance of hydraulic jacks is optimized through quality checks and design improvements.

Control: Hydraulic jacks work principally on fluid but it’s important to control that fluid for the mechanism to work. This is done by a control valve. The control valve manages and adjusts the flow rate of hydraulic fluid in a hydraulic system. This allows for precise lifting and lowering, ensuring accurate and stable positioning of the load.

Hydraulic jacks come in several designs, each typically suited for specific tasks:

Bottle Jacks: Bottle jacks, so-called due to their resemblance to a milk bottle, are compact tools that are relied upon for heavy-duty lifting in the construction and mining sectors. They handle significant weights while fitting into tight spaces.

Toe Jacks: Just as the name suggests, toe jacks help in lifting heavy loads from the base, or ‘toe’. They find their main use in industrial settings, cement and construction projects. They are designed with a low-profile base and are used in tight or confined spaces.

Strand Jacks: Strand Jacks claim a dominant position in heavy-duty lifting. These jacks function using steel cables, or ‘strands’. Their lifting capacity makes them perfect for applications such as bridge and building construction.

Hydraulic jacks are versatile tools employed in various industries due to their efficiency and effectiveness in heavy lifting:

Automotive Industry: Automotive manufacturing and repair facilities utilize hydraulic jacks to allow operators to inspect and work on the vehicle’s undercarriage. They use jacks to raise and lower vehicles, with a high degree of precision and control.

Construction: Construction industries deal with heavy loads such as pieces of construction material, equipment, or entire structures. Hydraulic jacks are used on construction sites to lift and shift machinery and other loads. Other hydraulic jacks also feature in equipment such as forklifts and bulldozers in elevator systems in low and medium-rise buildings. Additionally, lifting equipment like cranes and hoists often incorporate hydraulic jacks for enhanced lifting capabilities.

Railroad and Transportation: Hydraulic jacks enable workers to raise and lower rails to place them on the track system precisely.

Mining: Mining deals with large chunks of rocks and that presents itself as a huge obstacle to mining processes. Hydraulic jacks allow a safe and controlled method of moving these large pieces of rock or other debris.

Marine Industry: Hydraulic jacks when used in the marine industry facilitate the construction of ships and are used to load large components onto finished boats and ships.

Agriculture: Agriculture utilises tools and equipment that need to be used at the proper height. Hydraulic jacks help to lower and raise tools to function at the ideal height.

Hydraulic jacks offer several advantages, making them a preferred choice for various lifting tasks:

Compact size: Hydraulic jacks are significantly smaller than other heavy-lifting solutions. This makes them a convenient choice for tightly packed areas. The storage footprint of a hydraulic jack is just a few square feet.

Efficient Lifting: Hydraulic jacks utilize mechanical advantage to lift heavy loads with minimal physical effort. This reduces the effort the operator would have to make and subsequently time is also used efficiently. It is important to consider the weight of the object when choosing a hydraulic jack to ensure it matches the lifting capacity required. Additionally, understanding the load capacity of the jack is crucial for safe and effective lifting.

Flexible and user-friendly: Operators don’t need special licenses or expensive training to operate hydraulics. Due to Pascal’s law to magnify force, a hydraulic jack can use its energy more efficiently and be more productive and efficient. Some hydraulic jacks rely on external hydraulics but many can be operated manually.

Versatility: Hydraulics come in many forms adapting to a wide range of settings based on the industry and usage. Their versatility ensures effective handling of different lifting needs.

High-quality industrial tools for efficient and reliable performance in construction, manufacturing, automotive, aerospace, and more.

Find Out MoreHigh-quality industrial tools for efficient and reliable performance in construction, manufacturing, automotive, aerospace, and more.

Find Out More

Contact Us

Contact Us