Products & Services Industry Guides

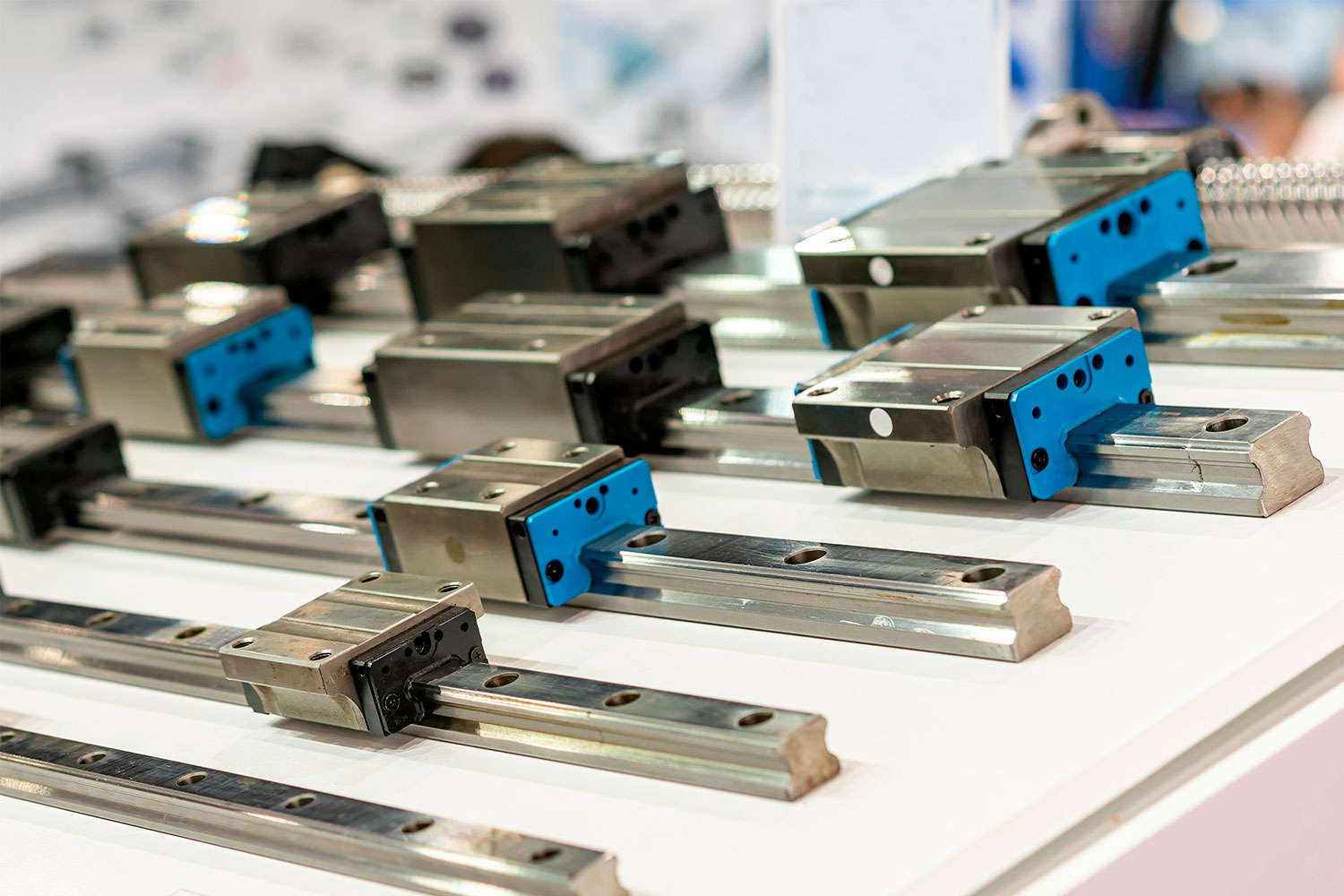

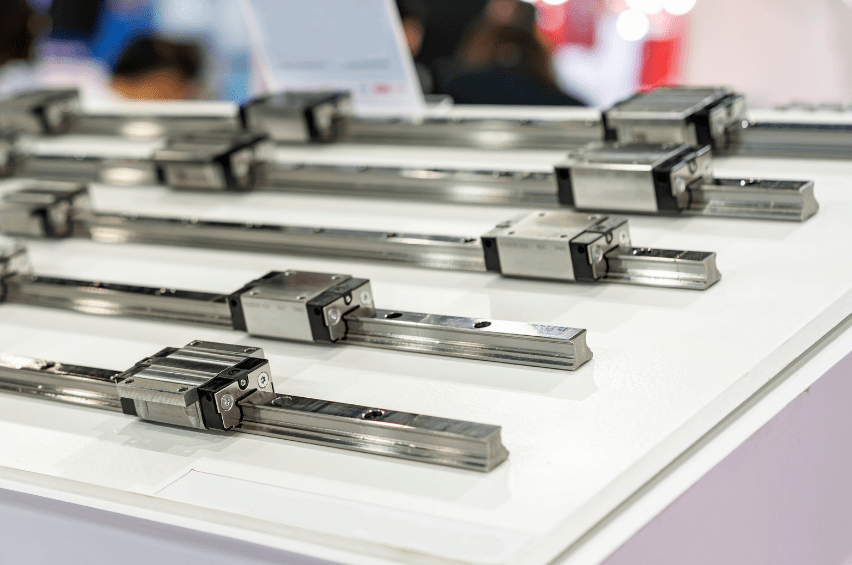

Linear Guides, also known as Linear Rails comprise carriages and rails which ensure a smooth and optimal linear motion along a straight path.

Their efficiency is what makes them essential in linear motion systems, together with Linear and Roller Bearings. Linear guides are used in a variety of products including semiconductor manufacturing equipment, medical devices, and the robotic industry.

This article will guide you on how to quickly choose the right linear guides for your smooth operation and applications!

When selecting a linear guide, you must be mindful of your operational needs and requirements to not compromise its ability and performance. Here are some mistakes to avoid when selecting linear guides:

Mistake 1: Disregarding alignment that will affect linear guides' performance. Choose your linear guide with a proper and specific alignment as applications with high accuracy also require more careful selection.

Mistake 2: Consider mounting tolerances of your linear guide to avoid flatness of the mounting surfaces and adding preload into the linear guide system.

Mistake 3: Not specifying preload correctly. Properly specified preload can reduce vibration, noise and heat while an improperly specified one can significantly increase them and degrade system performance.

Mistake 4: Neglecting the effect of materials and plating. These factors are often treated as less important when selecting linear guides despite having a significant effect on not only the project but also from a performance standpoint, cost and lead time.

In case of failures and maintenance concerns, SLS offers a specialised integrated solution to control any mishandling with fast response time to minimise your downtime. Our in-house engineering team, SLSPRO is ready and equipped with just the solutions for you!

Carefully selecting the right linear guide is crucial to ensure it meets the specific demands and helps in achieving optimal performance for your machine. When selecting linear motion products, the factors to be considered include:

Load capacities: This can be determined by its maximum force, for static (mass x gravity) and dynamic (mass x acceleration) movement as stated by matara.com.

Corrosion resistance requirements: Different machine tools require different resistance, such as pharmaceutical equipment compared to machines used for food industries.

Size & scale: Ranging from heavy-duty to compact, or somewhere in between.

Types of support arrangement: To ensure the support components in your application can allow the linear guides to function as intended.

Similar to many other linear bearings and other engineering products, linear guides come in various configurations to cater to diverse motion control needs. From profile rails setups to flat guides, there are practical solutions and features for machine tools.

It comes with a profiled shape rail and carriage. The rail typically has a "T" or "H" profile, and the carriage is designed to fit and move along this profile.

The high rigidity movement and the contact between the carriage and the profiled rail can reduce friction, making it the most commonly used linear guide in industrial machinery and automation system.

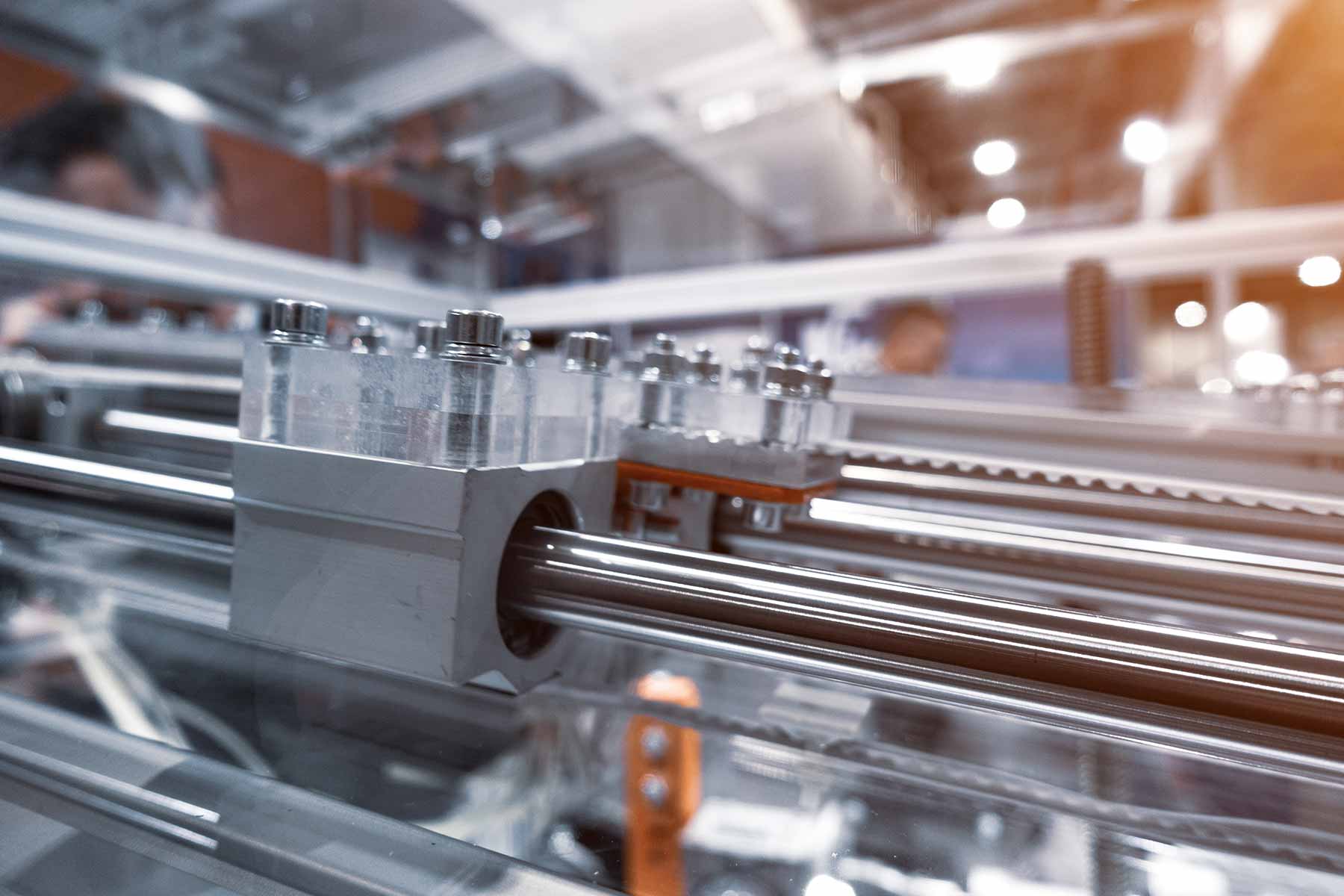

Unlike square rails, it comes cylindrical. The configuration consists of a carriage and round rail that rolls along the cylindrical shape.

The round rail system is best known for its simple structure, ease of installation and economical cost.

While it does not have the same high rigidity as profile rail in terms of its movement, industries such as woodworking and handling material which require moderate load capacity and precision, benefit from round linear guides the most.

In conclusion, the selection of linear guides is critical for achieving optimal performance for your linear motion system.

Whether you are opting for profile, flat, round or square guides, choosing wisely ensures seamless and easy mechanical operation.

With a commitment to quality and innovation, SLS Bearings ensures that its linear guides collection delivers products of the highest quality and reliability.

Our extensive set of linear guides will also help you pick just the right configuration for your operational needs!

Get in touch with us to find out which linear guides suit your operation best!

Precise tracks ensure smooth and accurate linear motion in machinery.

Find Out MorePrecise tracks ensure smooth and accurate linear motion in machinery.

Find Out More

Contact Us

Contact Us