Due to its ability to facilitate rapid, accurate, and effective production processes, automation has become a crucial component of industries all over the world. Many automated processes, such as conveyor systems and robotic arms, mainly depend on linear motion systems. The structural support required for precise and seamless motion is provided by linear shafting support rails, one of the key parts of these systems. By guiding linear shafts, these systems make sure they stay aligned and can withstand the forces of high-speed operations. This article examines the automation function of linear shafting support rails, their technological advancements, and how they enhance accuracy, lessen vibration, and facilitate high-speed operations.

The Role of Linear Shafting Support Rails in Automation

They guide and support the linear shafts that drive different mechanical components and linear shafting support rails are essential to automation. They aid in maintaining the shafts' correct alignment while they move, offering accuracy and stability all along the way. In many automated applications where accuracy and dependability are crucial, like robotic arms, conveyor systems, and CNC machines, these support systems are indispensable.

Because automation systems work at high speeds and under heavy loads, it's critical to reduce vibrations and misalignment that could cause mistakes or failures. A stiff framework that avoids these problems and guarantees the smooth operation of the entire system is provided by linear shafting support rails. Whether it’s guiding a robotic arm along a specific path or controlling the motion of a conveyor belt, the rails ensure that the components remain in perfect alignment, optimising performance and productivity.

What Are Linear Shafting Support Rails?

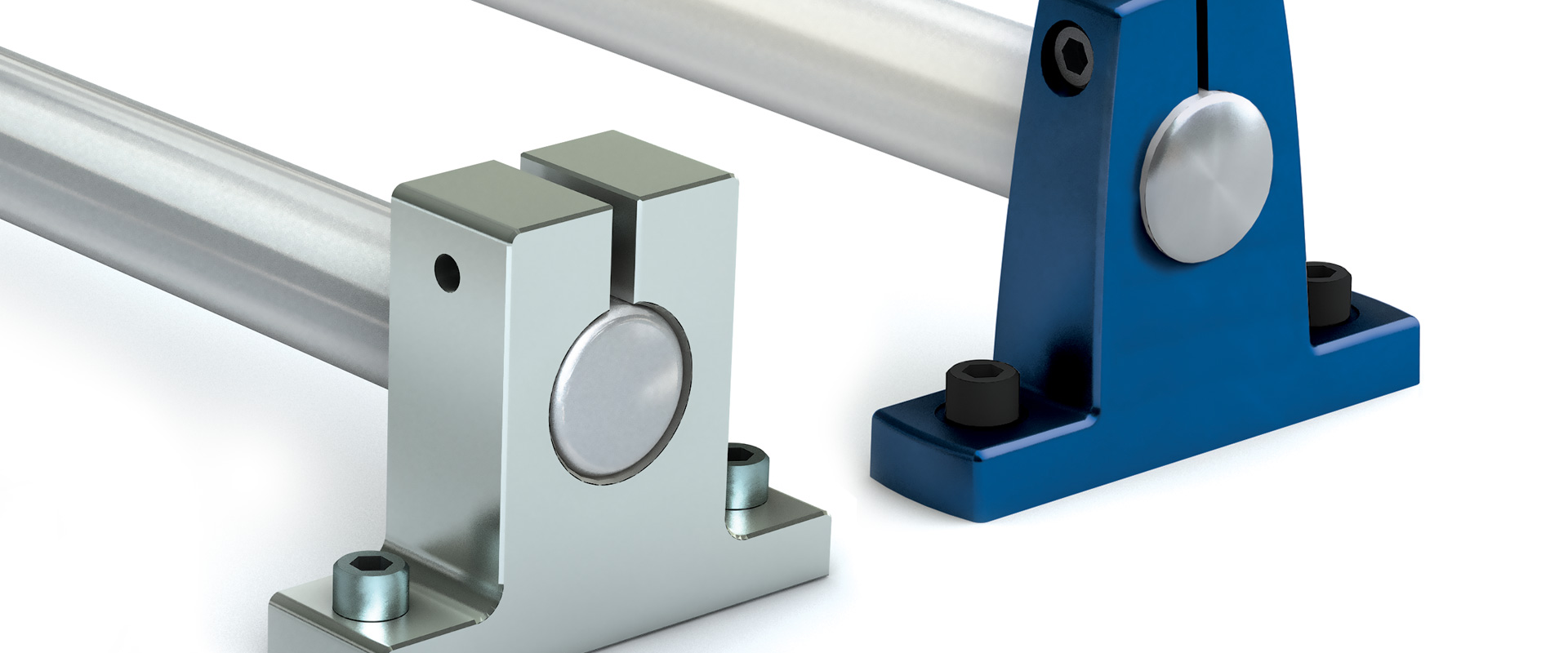

To provide stability and direction to linear shafts within motion systems, linear shafting support rails are mechanical parts. These rails can tolerate large loads, fast motions, and challenging operating conditions because they are usually made of high-strength materials like aluminium or stainless steel. In order to prevent any lateral movement and maintain correct alignment, the rails act as a track that secures the linear shafts in place. A rail that runs parallel to the linear shaft and has sliding mechanisms or bearings to enable smooth motion along the rail is the fundamental component of linear shafting support rails. Various sizes and configurations of these rails are available based on the particular needs of the application. Some systems include features such as integrated lubrication mechanisms to reduce friction, while others may have additional support structures to handle higher loads or longer shafts.

How Linear Shafting Support Rails Improve Precisoin in Robotics

For tasks like assembly, inspection, and manipulation in robotics, accuracy is essential. Because they guarantee that the robotic arms or tools move in a straight line with little deviation, linear shafting support rails are essential to preserving the accuracy of robotic systems. Errors in the robot's movements could result from linear shafts that are bent, twisted, or misaligned due to inadequate support.

Linear shafting support rails guarantee that the robotic system stays aligned while in use by offering a sturdy and rigid platform. This lessens the possibility of any unintended movements that might result in incorrect positioning or a failure to meet tolerance requirements. For sectors like electronics, auto manufacturing, and pharmaceuticals, where even minor mistakes can lead to faulty products, the accuracy provided by these systems is crucial.

Ensure Accurate Linear Motion

Many

automated systems are built on the foundation of precise linear motion. Whether using a conveyor system, CNC machine, or robotic arm, accurate movement is crucial to producing high-quality output. By stabilising the shafts and directing them along their intended path, linear shafting support rails guarantee that linear motion stays constant. Backlash, mechanical mistakes, and departures from the intended movement are reduced by this exact guidance.

For instance, linear shafting support rails help keep the shafts from moving out of alignment, ensuring that the tool maintains its position in relation to the workpiece in CNC machines where the cutting tools must move along a predetermined path with extreme accuracy. As a result, there is less material waste and better cuts. Similarly, in robotics, where the robot’s end effector must move precisely to pick up or place items, linear shafting support rails keep the system aligned, ensuring that the movements are accurate and repeatable.

Reducing Vibration and Misalignment

Two frequent problems that can impair automated systems' performance are vibration and misalignment. While misalignment can cause uneven component wear and tear and early failure, vibration can cause shaking or undesired movement, which can impair the system's precision.

By giving the linear shafts a sturdy framework, linear shafting support rails help to alleviate both of these problems. The system stays in alignment because the rails stop the shafts from vibrating or moving laterally while in use. This prolongs the system's lifespan and lowers maintenance costs by increasing precision and decreasing wear on moving parts. Furthermore, by minimising vibration, the support rails help prevent errors in operations that require precise motion control, such as in robotic arms or CNC machines.

Supporting High-Speed Operations

High-speed automation is required in many industries to maintain efficiency and meet production demands. High-speed operations, however, present extra difficulties, especially when it comes to preserving stability and accuracy. By giving linear shafts a sturdy base on which to run at high speeds, linear shafting support rails aid in overcoming these difficulties.

Even minor vibrations or misalignments at high speeds can result in serious problems like decreased accuracy, faulty products, or equipment failure. By maintaining the shafts' proper alignment and stability even at high speeds, linear shafting support rails mitigate these issues. This guarantees that the system runs efficiently without sacrificing accuracy or performance. For instance, linear shafting support rails in conveyor systems ensure that moving parts are properly aligned, allowing goods to be moved at high speeds without any disruptions or errors.

Applications of Linear Shafting Support Rails in Automation

Linear shafting support rails are widely used across a range of automated systems where precision and reliability are crucial. Some of the most common applications include robotic arms, conveyor systems, CNC machines, and automated assembly lines. Let’s explore these applications in more detail:

- Robotic Arms and Pick-and-Place Systems: Linear shafting support rails are crucial for precise and accurate movements in robotic arms, particularly those utilised in pick-and-place systems. These robots frequently have to pick up objects and put them in precise places with little error. In order to prevent misalignment and guarantee that the robotic arm moves precisely as needed, the support rails maintain the shafts' alignment. This is especially crucial in sectors like electronics where precise component placement is required.

- Conveyor Systems and Material Handling: In sectors like factories, logistics hubs, and warehouses that depend on material handling, conveyor systems are essential. Conveyor belt movement is guided by linear shafting support rails, which guarantee a steady, precise, and smooth flow. The rails avoid problems like jamming or uneven movement that could interfere with the material handling process by offering stability and minimising misalignment.

- CNC Machines and Automated Assembly Lines: Precision linear motion is necessary for automated assembly lines and CNC machines to carry out operations like drilling, cutting, and assembling. To guarantee that the shafts in these systems stay aligned and permit precise and seamless movements, linear shafting support rails are utilised. This is crucial for preserving product quality and guaranteeing accurate and efficient manufacturing procedures.

Advancements in Linear Shafting Support Rail Technology

As automation continues to evolve, so too does the technology behind linear shafting support rails. Several advancements have been made to enhance their performance, durability, and efficiency. Some key developments include:

- Advanced Materials: New materials such as ceramic composites and high-strength steel alloys are being used to improve the durability and resistance to wear of linear shafting support rails.

- Integrated Bearings and Lubrication: Modern systems incorporate advanced bearings and integrated lubrication systems that reduce friction and wear on the rails and shafts, improving performance and extending their lifespan.

- Smart Technology: The integration of sensors and smart technology allows for real-time monitoring of the system, detecting issues like misalignment or excessive vibration before they lead to failure. This enables predictive maintenance, reducing downtime, and improving system efficiency.

A vital part of automated systems, linear shafting support rails guarantee accuracy, lessen vibration, and facilitate high-speed operations. These rails are essential for preserving the stability and alignment of linear shafts, which guarantees precise and fluid motion in robotic arms, conveyor systems, CNC machines, and automated assembly lines. The reliability and performance of linear shafting support rails in contemporary automation systems are further enhanced by developments in materials, lubrication, and smart technology. The significance of linear shafting support rails in guaranteeing accuracy and efficiency will only increase as industries strive for quicker, more effective production processes.

For those seeking professional assistance or specialised expertise in dealing with pneumatic valves, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

linear shaft support rails selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us