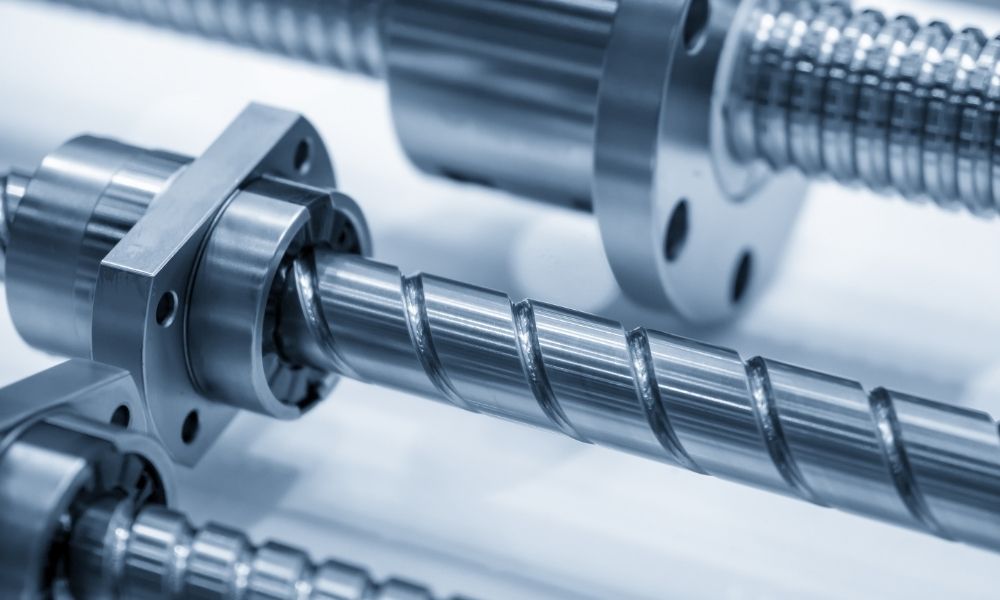

In order to facilitate efficient and smooth linear motion, linear bearings are crucial parts of machines and systems. They guarantee precise machine operation by lowering wear and friction while bearing loads. Contamination, however, is one of the biggest risks to the lifespan and performance of linear bearings. Dirt, dust, moisture, and foreign particles are examples of contaminants that can impair these bearings' performance, resulting in early failure, increased wear, and expensive downtime. This article will discuss the common contaminants that affect linear bearings, the reasons why contamination poses a threat to them, and the best ways to avoid contamination, such as controlled environments, frequent cleaning, and adequate sealing.

Why Contamination is a Threat to Linear Bearings

Linear bearing contamination can seriously harm the bearing as well as the machine it supports. Contaminants can upset the balance that bearings are meant to maintain by lowering friction between moving parts. The bearing surfaces may deteriorate as a result of increased friction brought on by dirt, debris, or moisture entering the bearing system. If left unchecked, this can lead to decreased performance, noise, vibrations, and even total bearing failure.

Furthermore, contamination can cause metal parts inside the bearing to rust and corrode, particularly when moisture or corrosive particles are present. This speeds up the bearing's deterioration, which could result in malfunction or the system breaking down entirely.

Common Contaminants Affecting Linear Bearings

Several types of contaminants can damage linear bearings, each posing unique risks to their performance. The most common contaminants include:

- Dust and Dirt: These are arguably the most prevalent and obvious pollutants. Abrasive wear on the bearing surfaces can result from dust and dirt particles entering the bearing system through environmental exposure. This eventually causes friction, surface damage, and failure.

- Water and Moisture: Bearings, especially those composed of steel or other ferrous metals, are susceptible to rust and corrosion from moisture. The lifespan of linear bearings can be considerably shortened by even minute amounts of moisture or humidity.

- Metal Debris: Excessive wear can be caused by metal particles entering the bearing from nearby machinery or worn parts. These particles frequently damage the rolling elements and races inside the bearing by producing a grinding effect.

- Chemical Contaminants: The materials in the bearing may deteriorate due to exposure to chemicals like acids or solvents, resulting in corrosion or other types of wear. Chemicals from lubricants, cleaning products, or other operations are frequently the cause of this kind of contamination in manufacturing settings.

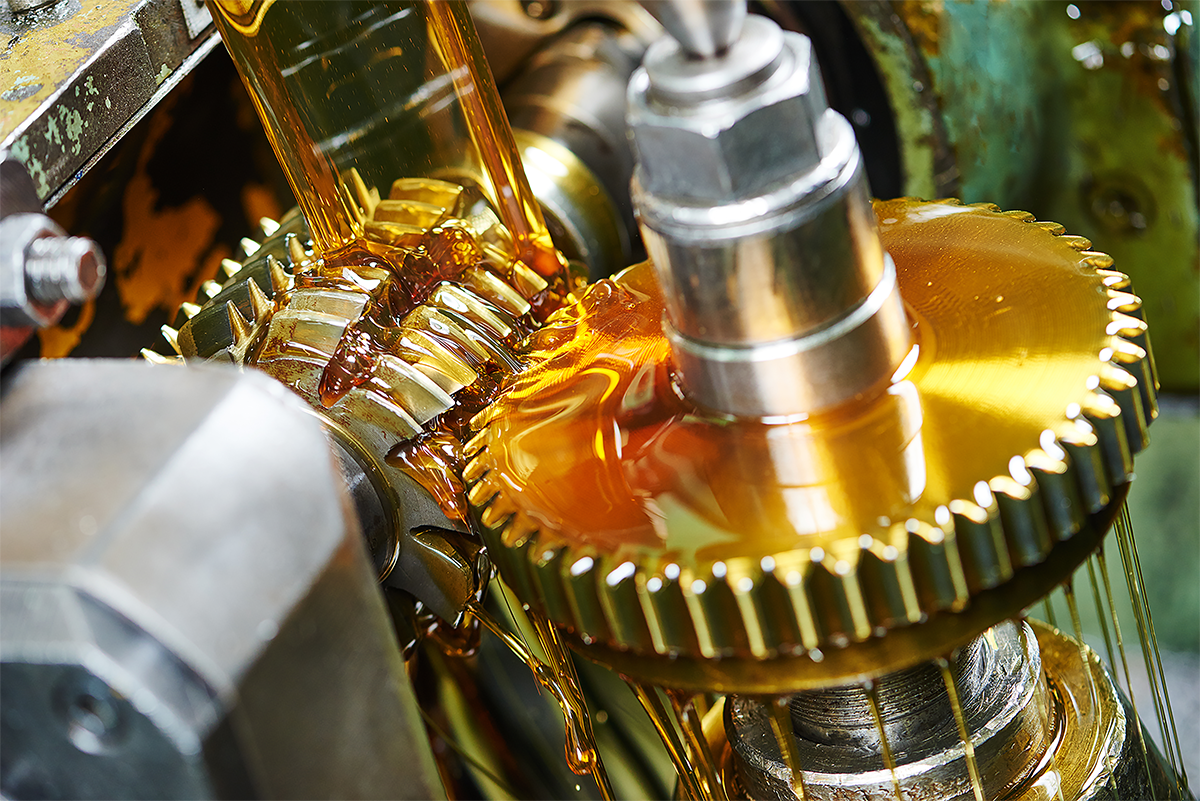

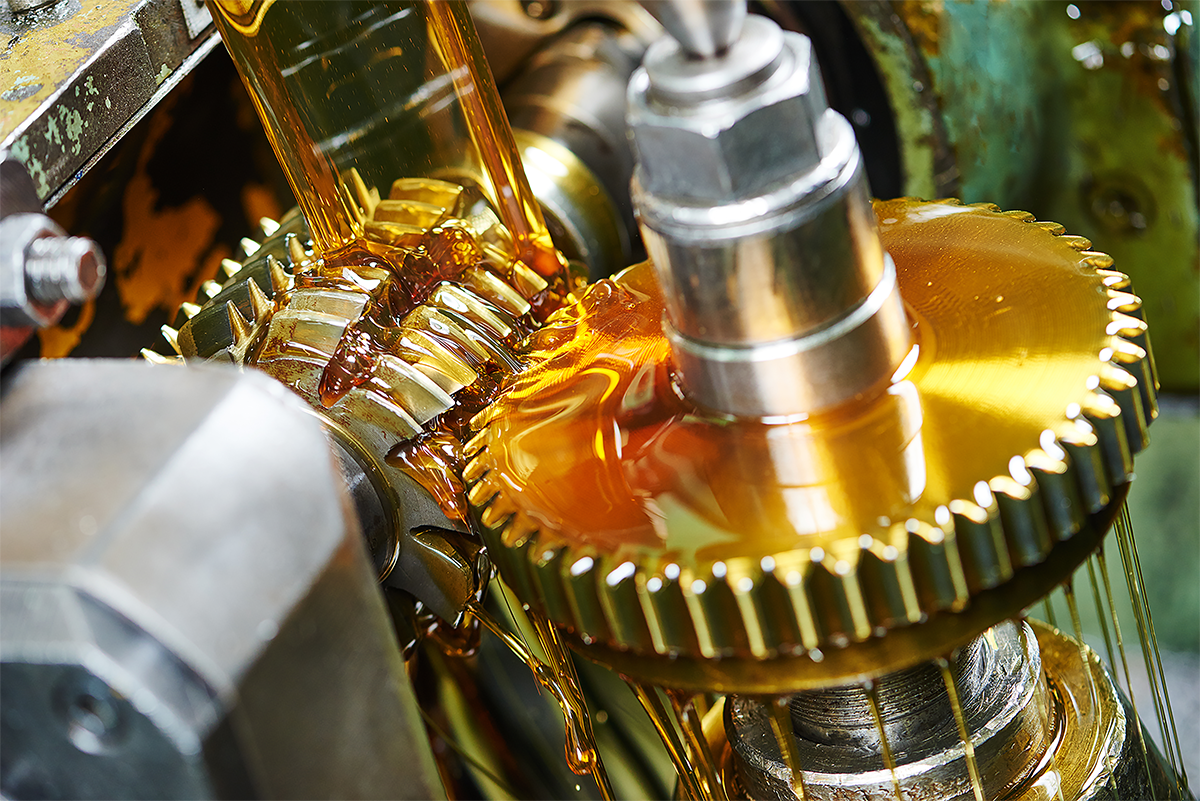

- Grease or Oil Contamination: Grease or oil loses its ability to effectively lubricate when it becomes contaminated with foreign particles. Increased friction from contaminated lubricants can hasten wear and lead to bearing failure.

Best Practices to Prevent Contamination to Linear Bearings

A proactive approach to both design and maintenance is necessary to prevent contamination in linear bearings. You can greatly lower the chance of contamination and guarantee your bearings' best performance by putting the following best practices into practice.

- Proper Sealing and Shielding

Appropriate sealing and shielding are two of the best methods to avoid contamination. Seals or shields that shield the internal parts from outside impurities can be installed on bearings. Shields provide an extra layer of protection, while seals aid in keeping debris, moisture, and other particles out of the bearing.

Seals come in a variety of forms, including lip, labyrinth, and radial seals, each intended for a specific use. The operating environment and the kinds of contaminants you anticipate coming into contact with will determine which sealing solution is best.

It's crucial to use sealed bearings in damp or dusty conditions. By preventing impurities from entering the bearing system, these seals help to preserve peak performance and increase the bearing's lifespan. - Regular Cleaning and Maintenance

In order to keep linear bearings from becoming contaminated, regular cleaning and maintenance are essential. Even the best shields and seals can deteriorate or wear down over time, letting impurities into the system. Regular cleaning and inspections assist in spotting possible problems before they result in serious harm.

Use the proper cleaning solutions for linear bearings that won't harm the bearing surfaces or interfere with the lubricant. To get rid of dirt and debris, you can use non-abrasive techniques like ultrasonic cleaning. In order to prevent contaminants from building up, it is also helpful to regularly replace outdated lubricants with new, premium grease or oil.

Maintaining the system's surrounding equipment also lessens the possibility of impurities getting into the bearing. Make sure all parts are properly aligned, and keep contaminants and debris out of the vicinity of the bearings. - Controlled Environment and Lubrication

The possibility of contamination can be considerably decreased by using linear bearings in a controlled environment. This entails keeping the area surrounding the bearing dust-free, dry, and clean. Contaminants can be avoided, for instance, by installing protective covers around machinery or employing air filtration systems.

Proper lubrication is crucial for reducing the effects of contaminants in addition to environmental control. In addition to lowering friction, the lubricant aids in cleaning the bearing surfaces of impurities. To guarantee appropriate protection and performance, use lubricants made for your particular bearing and application.

It is crucial to select the appropriate lubricant type according to the bearings' operating conditions. Over time, lubricants can break down or become contaminated, so it’s crucial to replace them regularly to maintain their effectiveness.

Signs of Contamination and How to Address Them

Recognising the signs of contamination early on can help prevent severe damage to linear bearings. Some of the key signs of contamination include:

- Increased Noise and Vibration: The bearing may move irregularly due to contaminants, which could result in excessive vibrations or noise. It may be a sign that the bearings in your machinery are contaminated if you hear strange noises or vibrations.

- Decreased Performance: Contamination can decrease the smoothness and precision of the bearing by increasing friction. The presence of contaminants may be the cause of a decline in your system's performance.

- Visual Inspection: In certain situations, a visual examination might reveal indications of contamination. Examine the area surrounding the bearing seals for dirt, rust, or discoloured grease. Additionally, you ought to look for any odd wear on the bearing surfaces.

Clean the bearing, replace the lubricant, and make sure the sealing system is intact right away if contamination is found. In extreme circumstances, a complete bearing replacement might be required.

Long-Term Benefits of Contamination Prevention in Linear Bearings

Preventing contamination in linear bearings offers several long-term benefits:

- Increased Bearing Lifespan: Preventing contamination lowers the possibility of wear and damage, greatly extending the bearings' lifespan.

- Reduced Downtime: Frequent upkeep and contamination control reduce malfunctions and guarantee that your equipment runs with few disruptions.

- Improved Efficiency: The overall performance of the system is improved by clean bearings because they operate more effectively, lowering friction and guaranteeing smoother movement.

- Cost Savings: The need for expensive repairs or bearing replacements is decreased when contamination is avoided. Additionally, it assists in preventing unscheduled downtime, which can be costly for companies.

Although contamination poses a significant risk to linear bearings, its effects can be considerably lessened with appropriate sealing, maintenance, and environmental controls. You can make sure that your linear bearings run effectively and last longer by adhering to best practices, which include routine cleaning, using the right seals and shields, and keeping an environment under control. Early detection of contamination symptoms and prompt remediation will ultimately save you time and money while enhancing the general functionality and lifespan of your equipment.

For those seeking professional assistance or specialised expertise in dealing with pneumatic valves, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our

extensive linear bearings selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us