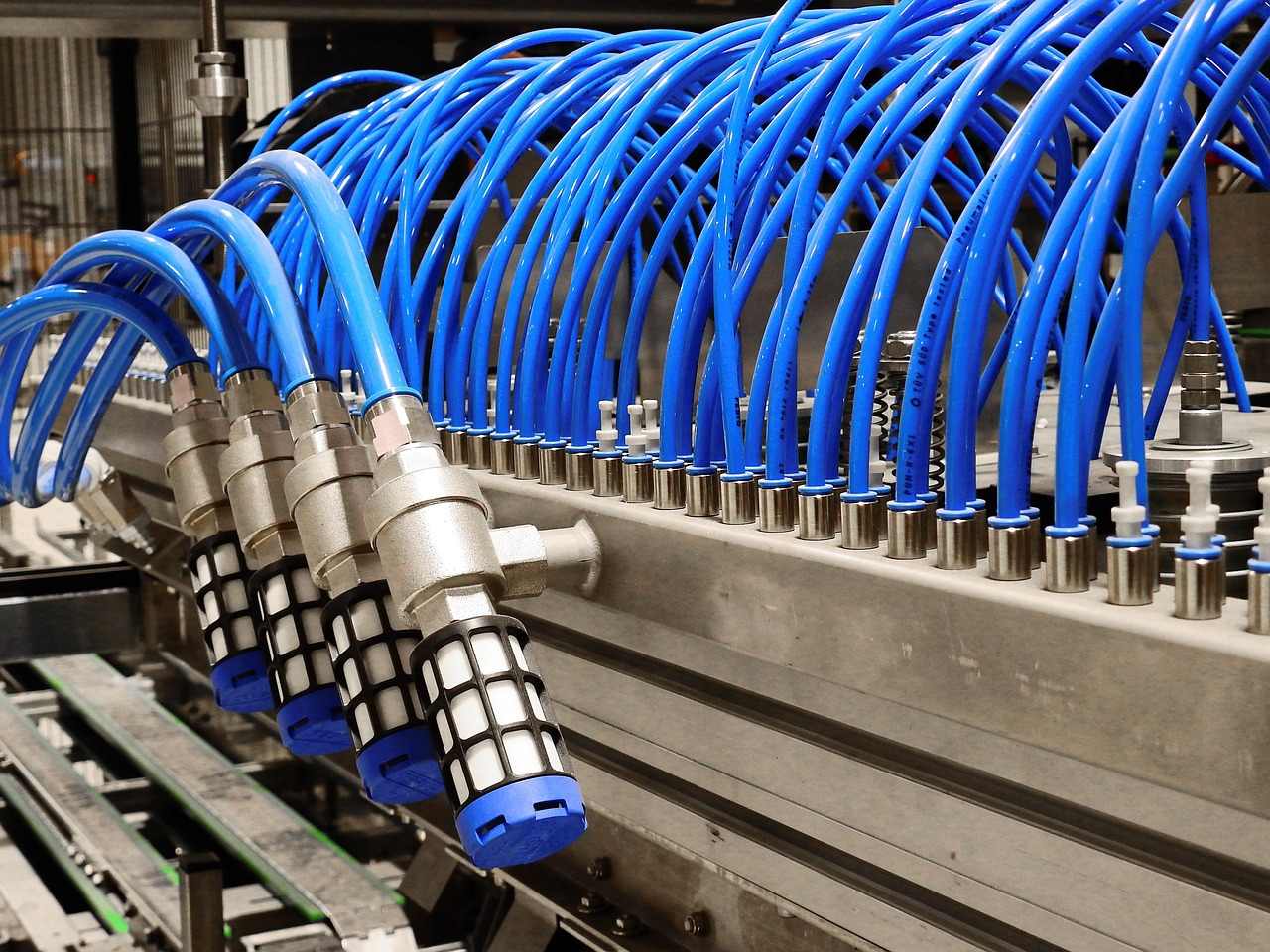

One of the leading causes of pneumatic valve failure is air contamination. Dust, oil vapour, and moisture can enter compressed air systems and build up inside valves, causing blockages or internal corrosion. Even small particles can prevent the valve from sealing properly or make it stick during operation.

When the air supply isn’t properly filtered, contaminants can also damage seals and spool surfaces, leading to air leaks and sluggish actuation.

How to prevent it:

Explore compatible air preparation and filtration components on SLS Bearings.

Incorrect installation is another frequent cause of pneumatic valve malfunction. Over-tightening fittings, misaligning ports, or failing to mount valves properly can create unnecessary mechanical stress or result in internal leaks. Incorrect valve position may also disrupt system operation and control accuracy. Additionally, improper construction or assembly of the valve can compromise its integrity and performance, and may negatively impact the actuator's operation, affecting its application in various construction, mechanical, and automation systems, and compromising the function of the pneumatic valve.

Even small alignment errors can lead to vibration and accelerated wear, especially in high-cycle applications.

How to prevent it:

For reliable industrial sealants and adhesives, visit our Adhesives & Sealants section.

Follow the manufacturer’s recommended torque specifications.

Verify that the valve ports are correctly matched to the pneumatic circuit.

Use the right sealing products to prevent leaks - such as thread sealants and gasket makers.

Like all mechanical components, pneumatic valves experience natural wear over time. Constant cycling, fluctuating air pressure, and exposure to contaminants can gradually degrade internal parts such as seals, spools, springs, and actuators.

As seals harden or lose elasticity, valves may start leaking air, slowing down system response and lowering efficiency.

How to prevent it:

Establish a predictive maintenance schedule based on operational hours or cycle counts, and consider the number of actuators in the system.

Replace seals, O-rings, and worn-out components during planned shutdowns.

Keep spare valve kits available for critical systems to reduce repair time.

Predictive maintenance is especially valuable for industries where downtime directly impacts production output - such as manufacturing and logistics facilities, where machine reliability is crucial, in Singapore’s industrial hubs.

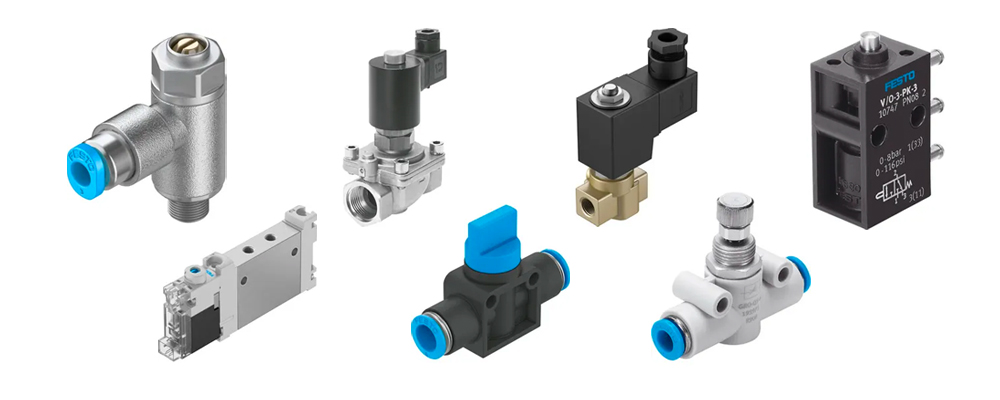

Each pneumatic valve is designed to operate within specific pressure and temperature ranges. In addition, different types of pneumatic valves are engineered for a range of flow rates and application requirements, ensuring suitability for various system needs. Control valves are specifically engineered to manage the direction and the flow of air in a pneumatic system, optimizing both airflow and system efficiency. Running the system above these limits can cause internal leakage, excessive friction, or even cracking of the valve housing.

Likewise, operating at low temperatures without proper lubrication can cause stiffness and delayed actuation. Actuators play a key role in valve operation, and the amount of power and energy required for proper function must be considered to ensure reliable performance.

How to prevent it:

Monitor air pressure regularly using calibrated gauges.

Maintain ambient and working temperatures within manufacturer recommendations.

Select valves rated for your specific application environment, whether in food processing, marine systems, or factory automation. It is important to choose the correct type and way (such as 3-way or 4-way) of valve, and ensure the outlet port configuration matches your system requirements.

When in doubt, contact our SLS technical specialists for guidance on valve selection.

Understanding the difference between valve types and their flow rates is crucial for achieving optimal system performance. The most advanced technology and accessories can further enhance the function and motion control of a pneumatic valve.

In solenoid-operated pneumatic valves, electrical issues can be just as damaging as mechanical ones. Coil burnout, loose wiring, or voltage fluctuations can lead to intermittent actuation or total valve failure.

Since many industrial systems rely on automated controls, electrical reliability is crucial to prevent unexpected shutdowns.

How to prevent it:

Conduct periodic inspections of electrical connections and coil resistances.

Ensure control panels have proper grounding and surge protection.

Replace coils showing signs of overheating or insulation wear before failure occurs.

Preventive checks of electrical components help maintain valve responsiveness and extend service life, especially in high-speed automated production lines.

Pneumatic valves are essential to keeping automated systems running smoothly. Yet, failures due to contamination, improper installation, wear, incorrect settings, or electrical faults can lead to costly downtime if left unchecked.

By investing in proper air filtration, predictive maintenance, and correct installation practices, you can ensure reliable valve performance and long-term operational stability.

Here at SLS Bearings, we offer a complete selection of pneumatic valves, fittings, filters, and sealants to help customers maintain efficiency and equipment longevity.

Ensure your pneumatic valves last for a long time without any breakdown. SLSPRO experts offer expert advice, specialised services, and premium support for industrial and automotive clients. Contact SLS for expert guidance on installation and maintenance of the right pneumatic valves.

Precision valves and terminals for optimal operation and efficiency.

Find Out MorePrecision valves and terminals for optimal operation and efficiency.

Find Out More

Contact Us

Contact Us