In the demanding worlds of mining and manufacturing, every component matters. One unsung hero that keeps operations running smoothly under extreme pressure is the tapered roller bearing. Known for their ability to manage both axial and radial loads, these bearings are critical in industries that rely on durability, precision, and efficiency. From supporting massive mining equipment to enabling the accuracy of CNC machines, tapered roller bearings are built to endure.

Let’s explore what makes these bearings indispensable across various industries and how innovations are shaping their future.

What Makes Tapered Roller Bearings Unique

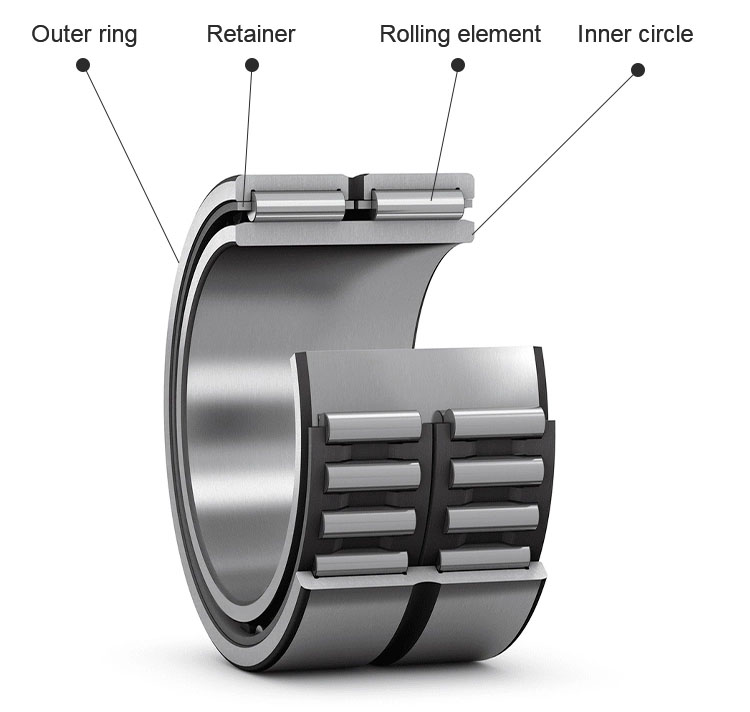

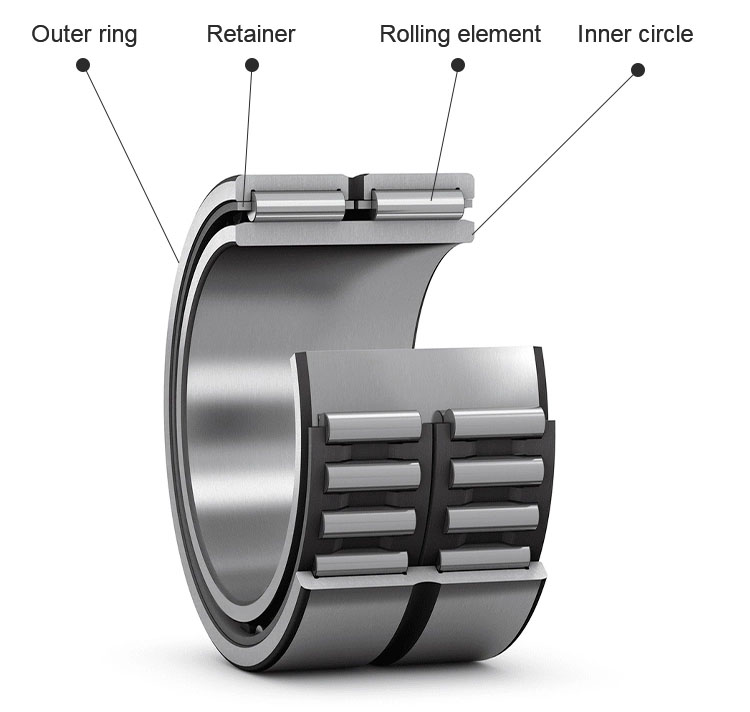

Tapered roller bearings are specifically designed to handle heavy-duty operations, especially where combined loads are present. Their tapered inner and outer ring raceways, along with the tapered rollers, enable them to withstand extreme stress while maintaining alignment and stability.

- Dual Load Handling Capability: These bearings manage both radial and axial loads simultaneously. This makes them ideal for applications where shafts experience force from multiple directions, such as in gearboxes or axles.

- Enhanced Contact Design: The tapered shape of the rollers increases contact surface between the raceways. This reduces stress concentration and improves overall load distribution.

- High Rigidity and Durability: Tapered roller bearings maintain high rigidity under load, which is crucial in applications involving torque or impact. This rigidity translates to reduced wear and extended service life.

- Adjustable Clearance: By adjusting the axial clearance, users can fine-tune the performance of the bearing to suit specific operational needs. This adjustability allows for more precise machinery function.

Endurance in Harsh Environments: Mining Applications

Mining operations place enormous physical and environmental demands on every mechanical component. Tapered roller bearings are chosen for these rugged conditions due to their unmatched resilience.

- Resistance to Contaminants: Mining environments are rife with dust, debris, and slurry. Tapered roller bearings are often used with advanced sealing systems to prevent ingress and prolong operational life.

- Shock Load Absorption: Equipment like haul trucks, crushers, and conveyors often encounter high-impact loads. The construction of tapered roller bearings allows them to absorb and distribute these shock loads without distortion.

- High Load-Carrying Capacity: Mining machinery involves heavy lifting and grinding operations. These bearings carry exceptionally large loads over long periods without compromising structural integrity.

- Thermal Stability: Bearings in mining applications face temperature swings due to heavy usage or weather. Tapered roller bearings are manufactured to maintain performance across wide temperature ranges.

Precision and Speed: Their Role in Manufacturing Machinery

In fast-paced and precision-driven manufacturing environments, tapered roller bearings provide the stability needed for optimal machine performance.

Maintenance and Performance Under Continuous Load

While known for their durability, even the most robust tapered roller bearings require routine maintenance to ensure peak performance over time.

- Lubrication Retention: Proper lubrication is essential to reduce friction and prevent overheating. New bearing designs feature optimised cages to retain and distribute lubrication efficiently.

- Wear Detection and Early Diagnostics: Modern sensors and smart systems can monitor vibrations and temperatures in real time. This allows plant managers to detect early signs of wear and plan proactive maintenance.

- Reduced Downtime: High-quality tapered roller bearings, when well-maintained, significantly reduce unexpected equipment breakdowns. This leads to improved operational uptime and cost savings.

- Serviceability and Interchangeability: Bearings used in industrial equipment are often designed for easy replacement. This makes maintenance straightforward, minimizing production halts.

Innovations Driving the Future of Tapered Roller Bearings

As industries continue to evolve particularly with the rise of electric vehicles (EVs) and automated manufacturing so too must the bearings that support them. Tapered roller bearing technology is advancing to meet these new demands.

- Lean Lubrication for EVs: Companies have developed tapered roller bearings that perform even under lean lubrication conditions. This reduces the need for oil and allows for more compact EV gearboxes.

- Improved Seizure Resistance: New materials and cage designs help prevent bearing seizure when oil flow is limited, especially during EV cold starts or oil pump shut-off modes.

- Energy-Efficient Designs: Bearings are being optimised for reduced churning loss, meaning they waste less energy in high-speed applications. This is critical in achieving better fuel or electricity efficiency.

- Compact and Lightweight Builds: Modern tapered roller bearings are being downsized without compromising performance. Lighter bearings contribute to overall machinery weight reduction, particularly in automotive and aerospace sectors.

Whether deep underground in a mining site or driving high-precision tools on a factory floor, tapered roller bearings are the silent champions of industrial performance. Their ability to carry large loads, endure harsh environments, and maintain accuracy under continuous operation makes them indispensable.

At SLS Bearings, we understand how important it is to choose the right bearing for your unique application. With a vast portfolio of high-performance tapered roller bearings and a team of technical experts, we’re here to help you optimise for durability, efficiency, and long-term success.

From underground mines to factory floors, performance starts with the right bearings. SLSPRO experts offer specialised services and deep industry knowledge to help you select the perfect tapered roller bearing for your application. Contact SLS today for tailored solutions that deliver durability, efficiency, and long-term reliability.

Contact Us

Contact Us