In the ever-evolving landscape of automation and robotics, precision and productivity have become critical benchmarks for success. At the core of this revolution lies linear motion technology, a fundamental enabler that allows robotic systems to move with unmatched accuracy, reliability, and efficiency.

For companies looking to optimise manufacturing, medical applications, or any industry that benefits from robotic automation, understanding the role and advantages of linear motion systems is essential.

In this article, we dive deep into the fundamentals of linear motion technology, explore key components that enable seamless robotic movements, highlight its benefits, and examine real-world industrial applications where linear motion systems are making a measurable difference.

An Introduction to Linear Motion Technology and Its Role in Robotics

Linear motion, simply put, is movement along a straight line. Unlike rotational or circular motion, linear motion ensures that robotic arms and tools travel directly between two points without deviation. In this context, the body refers to the physical object or part of the robot that is being moved by the system. This characteristic is vital in robotics, where repeatability, positioning accuracy, and smooth operation are non-negotiable.

In robotic automation,

linear motion systems serve as the backbone for translating mechanical power into precise, controlled movements. For example, when a robotic arm picks up a delicate electronic component or performs a surgical procedure, the accuracy of the motion directly influences the outcome’s success. Linear motion technology makes this possible by offering predictable, friction-reduced movement along a predefined path.

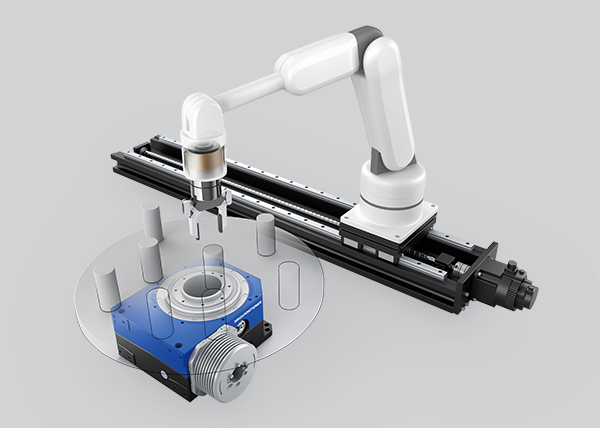

These systems integrate advanced components such as linear guides, rails, bearings, and actuators to ensure the robotic equipment functions with fluidity and precision. A linear guide plays a critical role in providing the precision and reliability required for robotic applications. When combined with sensors and intelligent control software, linear motion technology delivers the high-level performance robotics demand in industries ranging from automotive manufacturing to medical robotics.

Key Components That Enable Accurate and Smooth Robotic Movements

Achieving smooth and precise robotic motion depends on several key components working harmoniously within a linear motion system. These components enable robotic parts to move on a predefined path or track, ensuring accurate positioning. Linear motion typically occurs along one axis or dimension, allowing for controlled and predictable movement.

Bearings: Ball and Roller Bearings

Bearings are the rolling elements within the guides that minimize friction between moving parts. Ball bearings provide smooth, low-friction motion suitable for lighter loads and high-speed applications, while roller bearings handle heavier loads with greater rigidity and durability. The choice depends on the robotic system’s specific requirements.

Linear Actuators

These devices convert electrical, pneumatic, or hydraulic energy into linear displacement. Linear actuators power the robotic arm’s translation along the linear path, providing controlled and repeatable motion. Precision actuators are essential for tasks demanding micron-level accuracy.

Sensors and Encoders

Sensors continuously monitor the position, velocity, and acceleration of moving components. Encoders, in particular, translate mechanical movement into digital signals, allowing control systems to execute closed-loop feedback for real-time correction and enhanced accuracy.

Together, these components form a robust linear motion system that powers robotic automation with the precision, speed, and reliability modern industries require.

Types of Linear Motion

Linear motion can be categorised into two main types: uniform linear motion and non-uniform linear motion. Uniform linear motion is when an object moves in a straight line at a constant velocity, meaning there is no change in speed or direction, and the acceleration is zero. This ideal scenario is rare in everyday life due to the presence of external forces like friction and gravity, which can alter the motion of an object. Non-uniform linear motion, on the other hand, occurs when the velocity of an object changes over time, resulting in non-zero acceleration. This type of motion is more common, as most objects experience varying forces that affect their speed and direction. Understanding the differences between uniform and non-uniform linear motion is essential for designing systems that can accurately control the movement of objects, especially in environments where precision and reliability are paramount.

Benefits of Linear Motion Systems in Improving Productivity and Precision

Incorporating linear motion technology into robotic automation brings numerous advantages that directly impact operational efficiency and product quality. As a result, the outcome will be improved productivity and precision. To be a high-performing robotic system with linear motion technology means the system is capable of consistent, accurate, and reliable movement, ensuring optimal results in automation tasks.

- Superior Precision and Accuracy:

Linear motion systems ensure robots perform tasks with exceptional precision. Whether positioning a robotic arm within microns or aligning surgical tools, linear guides and actuators reduce mechanical play and friction that can introduce errors. This precision translates into higher quality outcomes, fewer defects, and more consistent product performance. - Increased Speed and Responsiveness:

With reduced friction and optimized component design, linear motion systems allow robotic components to move swiftly without sacrificing control. Faster movements mean shorter cycle times, increasing overall productivity on manufacturing lines or in automated processes. - Enhanced Durability and Lower Maintenance:

High-quality linear motion components from SLS are engineered for long-term durability. By minimizing wear and tear through advanced materials and precision engineering, these systems require less frequent maintenance, reducing downtime and operational costs. - Energy Efficiency:

Smooth, low-friction linear motion reduces the energy needed to operate robotic systems. This efficiency not only lowers power consumption but also decreases heat generation, extending component life and reliability.

- Versatility and Scalability:

Linear motion systems come in a range of sizes and load capacities, making them adaptable across industries. From compact medical devices requiring miniature guides to heavy-duty industrial robots, linear motion solutions can be tailored to specific needs, ensuring optimal performance.

Real-World Applications of Linear Motion in Automated Industrial Processes

The topic of linear motion applications in industry is essential for understanding how different types of motion contribute to automation and efficiency.

Linear motion technology underpins many robotic automation processes across diverse industries. Before diving into specific examples, we can observe the impact of linear motion in various industrial settings, where it enables accurate positioning and smooth movement.

Here are some key real-world applications where it drives precision and productivity:

- Automotive Manufacturing:

In automotive production lines, robots equipped with linear motion systems perform complex assembly, welding, and painting tasks. The precision and repeatability of linear guides and actuators ensure consistent build quality while enabling high throughput. - Electronics Assembly:

The assembly of delicate electronic components demands extreme accuracy and stability. Linear motion systems guide robotic arms to place tiny parts with micron-level precision, improving yield and reducing rework. - Medical Robotics:

Surgical robots rely heavily on linear motion technology for precise instrument positioning during minimally invasive procedures. The smooth, controlled motion reduces the risk of errors and enhances patient safety. - Logistics and Warehousing:

Automated guided vehicles (AGVs) and robotic pickers use linear motion to navigate warehouse environments efficiently. Reliable, accurate movement allows for faster order fulfillment and inventory management.

- Packaging Industry:

High-speed packaging lines benefit from linear motion systems to control the movement of robotic arms that sort, fill, and seal products. The technology supports rapid, precise, and repeatable operations essential for meeting production targets.

Conclusion

Linear motion systems are the driving force behind the precision and productivity improvements witnessed in modern robotic automation. Their ability to provide smooth, accurate, and reliable movement enables robots to perform complex tasks efficiently and consistently. From manufacturing floors to operating rooms, the applications of linear motion technology continue to expand, reshaping industries and enhancing operational capabilities.

Why Choose SLS for Your Bearing Needs?

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

By choosing high-quality linear motion components from SLS, businesses can ensure they remain competitive through superior automation performance. Ready to optimise your robotic automation with cutting-edge linear motion technology?

Contact SLS today and let us help you build the future of precision and productivity.

Contact Us

Contact Us