In industrial environments where machinery drives productivity, fan belts are small but essential components that directly impact plant efficiency. These belts connect rotating parts like pulleys and shafts, helping drive essential equipment such as pumps, fans, and compressors. Fan belts must withstand significant loads as they transfer power between these components, making belt strength and durability crucial for reliable operation. When a fan belt fails, the ripple effect can bring operations to a halt, causing costly downtime, equipment damage, and safety concerns. That’s why preventive maintenance is not just a good practice; it’s a critical strategy for operational excellence.

Let’s explore why maintaining your fan belts proactively can lead to better performance, fewer breakdowns, and higher returns on investment.

Understanding The Role of Fan Belts in Plant Operations

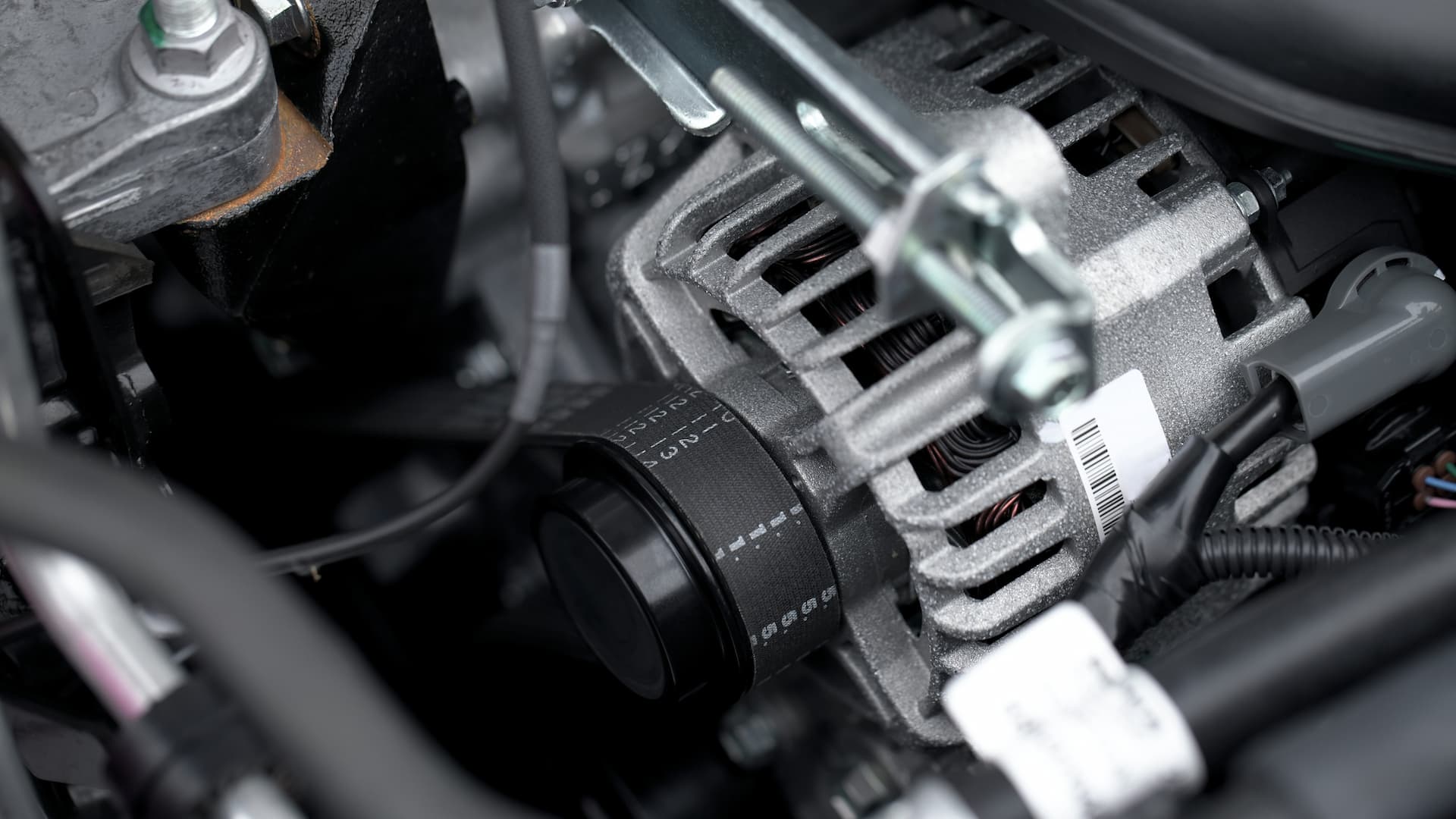

Fan belts are integral to mechanical systems that power your plant’s critical operations. They transfer rotational energy from one component to another, ensuring coordinated motion and efficient equipment performance. Their function may seem minor, but their failure can interrupt major processes.

- Energy transmission efficiency: Fan belts help deliver mechanical power from engines to auxiliary systems, ensuring continuous equipment function without excessive power loss.

- Heat and ventilation control: In systems like industrial HVACs, fan belts enable fans and blowers to regulate airflow and prevent overheating.

- Support for hydraulic systems: Many hydraulic pumps rely on fan belts to maintain pressure levels, essential for automation and material handling.

- Smooth machine coordination: They synchronise multiple parts of complex machinery to work in unison, preventing delays and misalignment in production. Understanding the correct route the fan belt takes around pulleys is essential for ensuring proper alignment and efficient operation of the machinery.

- Operational safety: Fan belts also play a role in maintaining temperature and pressure, indirectly supporting safe plant conditions.

The High Cost of Fan Belt Failure

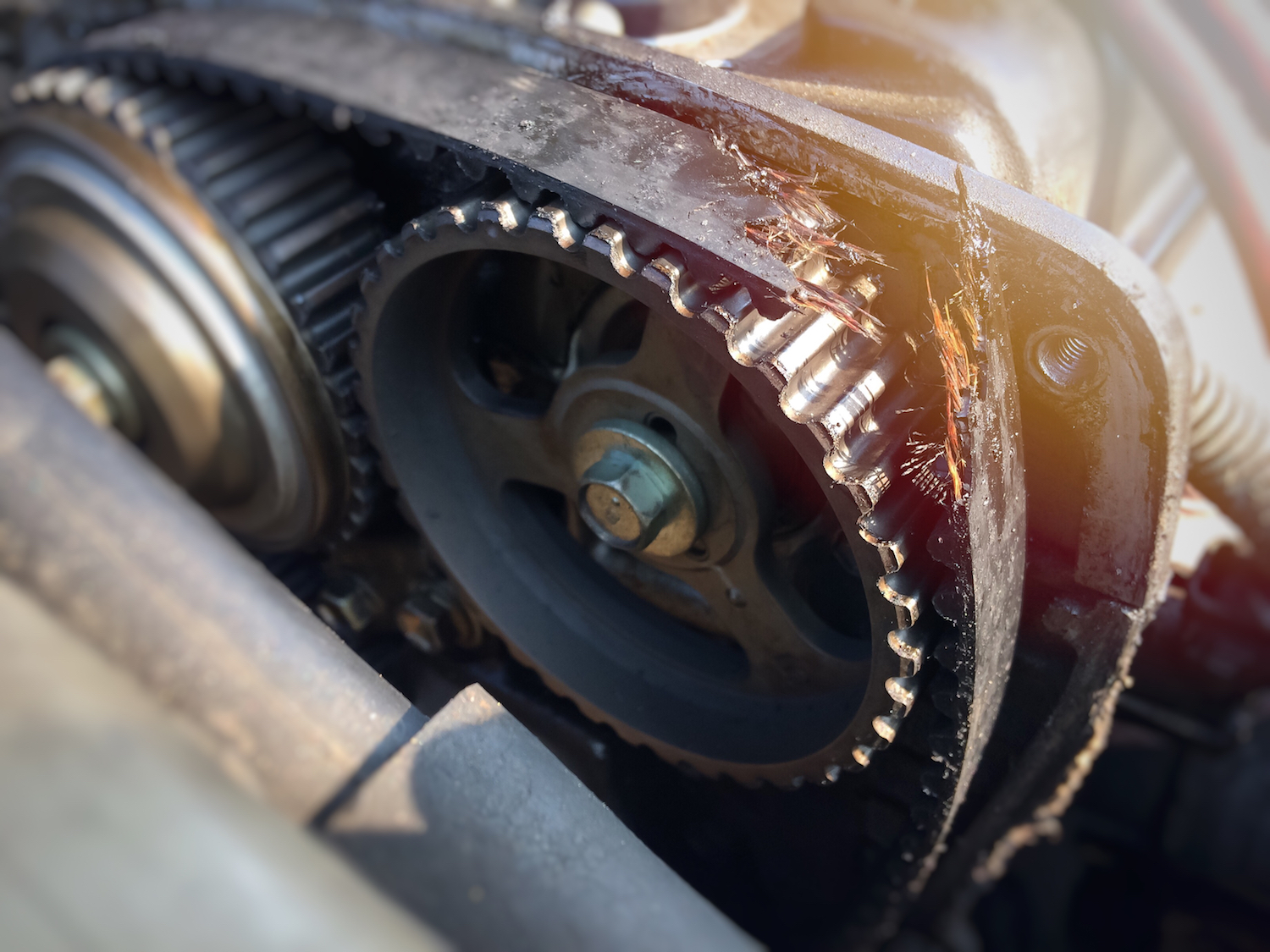

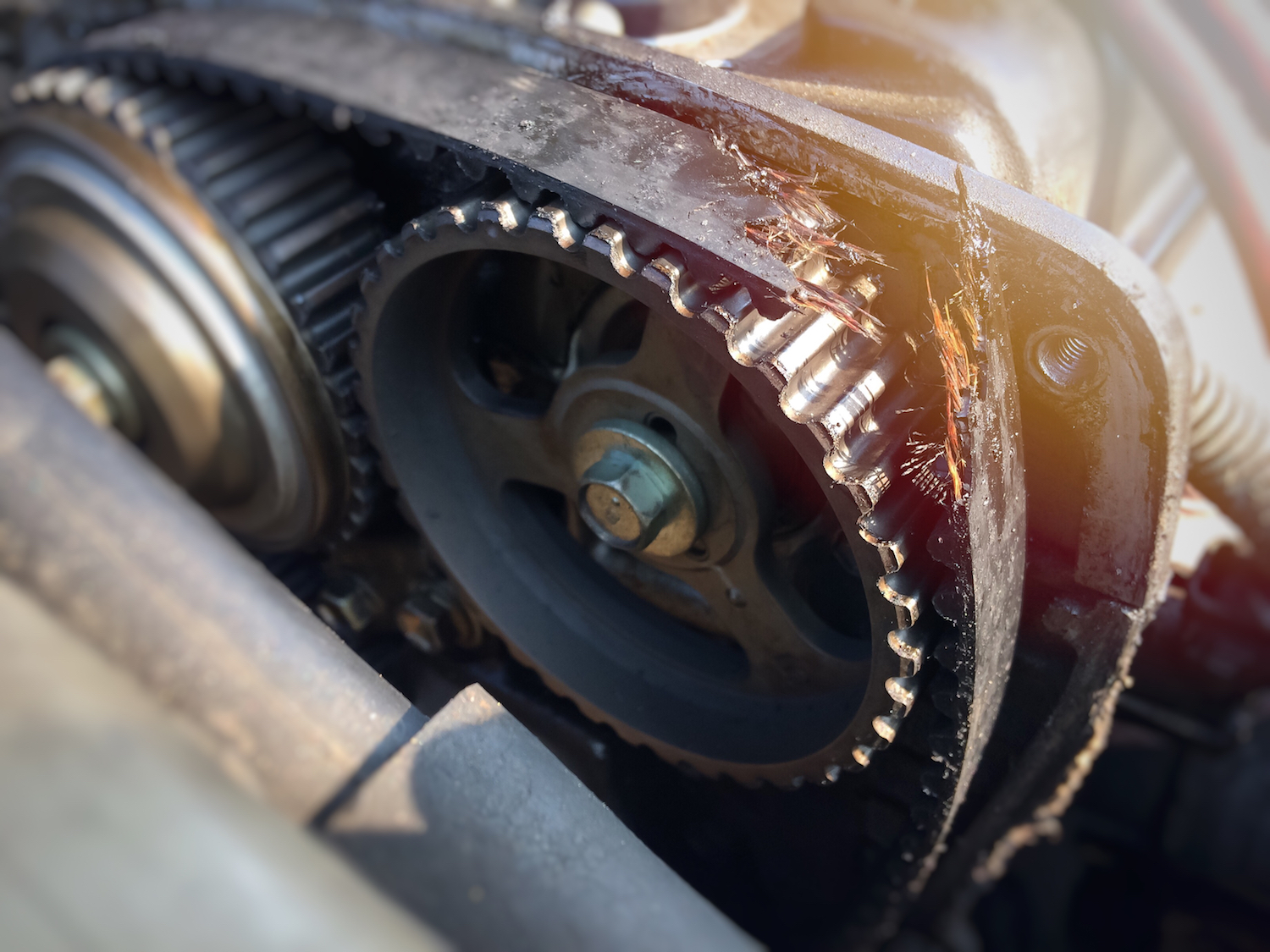

A broken or slipping fan belt may seem like a minor inconvenience, but the true cost goes far beyond the belt itself. From equipment downtime to emergency repairs, belt failure can be a costly disruption to any industrial plant.

- Downtime losses: When a belt fails, machinery stops working, and entire processes can come to a standstill, leading to production delays and financial losses.

- Equipment damage: A broken belt can damage connected components like pulleys, shafts, and bearings, escalating maintenance costs.

- Increased energy usage: Slipping or worn belts reduce mechanical efficiency, forcing motors to work harder and use more energy.

- Safety concerns: Sudden equipment failure can lead to overheating, pressure spikes, or component ejection, posing risks to workers.

- Emergency repairs: Reactive maintenance is always more expensive than scheduled preventive checks, especially when outside support or spare parts are needed urgently.

Benefits of Preventive Maintenance for Fan Belts

A preventive maintenance plan allows you to avoid unexpected equipment failures and extend the lifespan of your

fan belts. Regular inspections, proper tensioning, and timely replacements all contribute to smoother operation and greater cost efficiency.

- Extended equipment life: Consistent care reduces wear and tear on both belts and the systems they power, ensuring your machinery lasts longer.

- Reduced downtime: With regular checks and maintenance, you can identify potential belt issues before they lead to breakdowns.

- Cost savings: Preventive maintenance is more affordable than reactive fixes and helps avoid secondary damage to expensive components.

- Energy efficiency: Properly maintained belts reduce friction and slippage, allowing machines to operate at optimal energy consumption levels.

- Improved plant reliability: Scheduled maintenance ensures your systems are always ready to run, supporting your production goals consistently.

Key Practices for Effective Belt Maintenance

Knowing what to look for and how to act on potential issues is the foundation of an effective maintenance program. By following industry best practices, your team can ensure your belts remain in peak condition year-round. Always follow the correct order of steps during fan belt replacement and maintenance to prevent errors and ensure proper function.

- Conduct routine visual inspections: Look for cracks, fraying, uneven wear, or glazing on the belt surface to catch early signs of damage. Be sure to inspect both sides of the fan belt, as damage may not be visible on just one side.

- Monitor belt tension: Improper tension can cause slippage or premature wear; always use manufacturer-recommended specs and tools.

- Check alignment: Misaligned pulleys create uneven tension and wear, reducing belt lifespan and stressing connected components. Pulleys guide and tension the belt, so ensure all pulleys are properly aligned to prevent operational issues.

- Keep belts clean and dry: Exposure to oil, grease, or water can degrade belt material and lead to slipping or cracking.

- Record maintenance history: Maintain detailed logs of inspections, replacements, and adjustments to spot patterns and optimise future maintenance.

Making Belt Care Part of Your Plant-wide Strategy

Integrating

fan belt care into your broader maintenance strategy ensures consistency, accountability, and long-term efficiency. A plant-wide approach also allows coordination between departments, leading to fewer oversights and improved productivity.

- Establish maintenance schedules: Set up consistent timelines for belt inspections and replacements based on manufacturer recommendations and usage conditions.

- Train your team: Ensure technicians are trained in fan belt inspection, tensioning, and replacement to minimise errors and increase efficiency.

- Use quality parts: Invest in durable, high-performance fan belts from trusted brands to reduce replacement frequency and ensure compatibility.

- Leverage predictive tools: Use sensors or vibration analysis tools to anticipate issues before they become critical, integrating with your broader asset management systems.

- Align with reliability goals: Make fan belt maintenance part of your plant’s larger reliability and uptime initiatives to support a culture of proactive care.

Fan belts may be small, but their impact on your plant’s efficiency and safety is massive. By taking a preventive approach, you not only avoid the heavy costs of unexpected breakdowns but also support long-term equipment performance and energy efficiency. Regular belt inspections, tension checks, and proper alignment are simple yet powerful ways to keep your systems running smoothly. More importantly, when belt care is integrated into your overall plant maintenance strategy, you ensure consistent operations and long-term cost savings.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

Contact SLS for expert guidance and high-quality sprockets designed to withstand the toughest plant conditions.

Contact Us

Contact Us