Marine and shipyard conveyor systems operate in some of the harshest environments, demanding durable and reliable components. Among these, the chain sprocket plays a critical role in ensuring smooth power transmission and overall system efficiency. In power transmission systems, chain sprockets are often compared to belts and gears, with belts serving as another essential component for transmitting rotary motion efficiently alongside chains. Selecting the right sprocket can significantly impact performance, maintenance costs, and operational uptime. In this blog, we’ll explore everything you need to know about choosing the perfect chain sprocket for marine and shipyard conveyor systems.

An Overview of Chain Sprockets and Their Industrial Applications

A

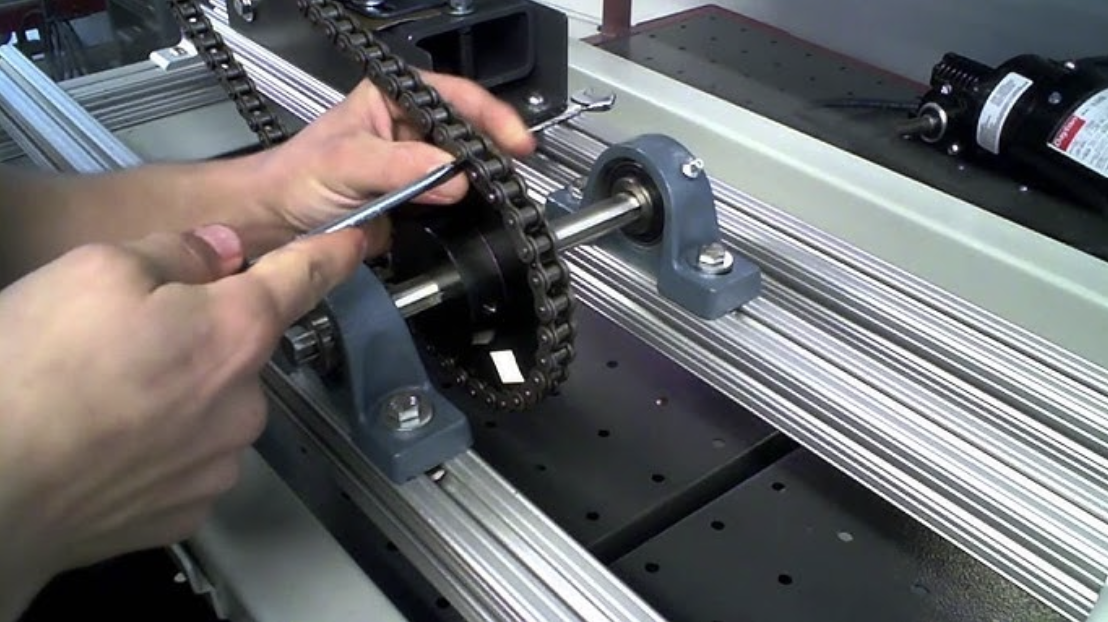

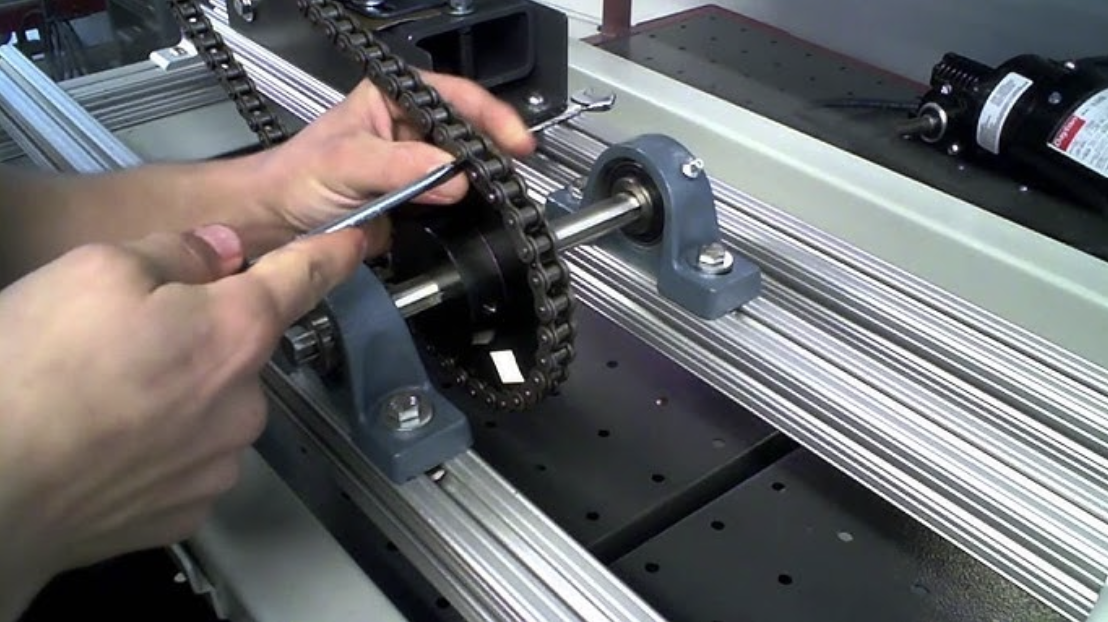

chain sprocket is a toothed wheel designed to engage with a chain to transmit rotary motion efficiently. Unlike gears, sprockets work by engaging the chain links, making them ideal for a wide range of industrial applications where power transfer over a distance is required.

In marine and shipyard environments, sprockets are commonly used in conveyor systems for transporting heavy materials, loading docks, and other mechanical systems where reliable, high-torque power transmission is critical. Their design allows for flexibility in speed control, torque management, and adaptability to different chain types and sizes, making them indispensable in such heavy-duty industrial settings.

Types and Applications of Chain Sprockets in Marine and Shipyard Settings

Chain sprockets are indispensable components in marine and shipyard operations, where they serve as the backbone for transmitting power and motion across a wide range of equipment. From propulsion systems and cargo handling machinery to onboard conveyors and cranes, the right sprocket ensures smooth, reliable operation even under the most demanding conditions.

Roller chain sprockets are especially prevalent in these environments due to their exceptional strength, durability, and resistance to corrosion. Designed to work seamlessly with roller chains, these sprockets deliver efficient power transmission, making them ideal for high-load and high-speed applications commonly found on ships and in shipyards. Whether moving heavy cargo or driving essential onboard systems, roller chain sprockets provide the robust performance required to keep operations running smoothly.

In shipyard settings, chain sprockets are found in a variety of equipment, including winches, cranes, and conveyor systems. Their ability to handle significant loads and maintain consistent performance under continuous operation makes them a preferred choice for shipbuilders and operators alike. The design of these sprockets takes into account the harsh marine environment, with many manufactured from high-strength steel or other corrosion-resistant materials to withstand exposure to saltwater and humidity.

The number of teeth on a sprocket, as well as the type and size of the chain used, are carefully selected based on the specific application and the loads involved. Larger sprockets and heavier chains are typically used for applications requiring the movement of substantial loads or operation at higher speeds, ensuring optimal performance and longevity.

Regular maintenance is essential for the reliable operation of chain sprockets in marine and shipyard settings. This includes proper lubrication of both the chain and sprocket, routine inspections for wear or damage, and timely replacement of components as needed. Such practices help maximise the lifespan of the sprocket and maintain the efficiency of the entire system.

The use of chain sprockets in these environments offers numerous benefits, including high efficiency, reliability, and adaptability to a variety of operational requirements. Their flexibility makes them suitable for a wide range of applications, from ship propulsion to cargo handling and beyond. In addition to roller chain sprockets, other types such as timing sprockets and drive chain sprockets are also utilised, each offering unique advantages tailored to specific operational needs.

As the demand for efficient and reliable power transmission solutions continues to grow in the marine industry, the variety of available sprocket designs and products ensures that there is a suitable option for every application. Chain sprockets remain a vital element in the performance and reliability of marine and shipyard equipment, supporting the ongoing evolution of these critical industries.

Key Factors to Consider When Selecting Sprockets for Marine Environments

Choosing a sprocket for marine conveyor systems involves more than just matching size and pitch with the chain. Here are some crucial factors to keep in mind:

- Load Capacity: Marine conveyor systems often deal with heavy loads. It’s vital to select sprockets that can handle the maximum expected load without premature wear or failure.

- Operating Conditions: Shipyards expose equipment to saltwater, moisture, and variable temperatures. Sprockets must be designed to perform reliably under these fluctuating and often corrosive conditions.

- Chain Compatibility: Ensuring sprocket teeth are perfectly matched to the chain pitch and thickness helps reduce wear and improves power transmission efficiency.

- Size and Pitch Diameter: These determine the speed ratio and torque applied, influencing overall conveyor system performance.

- Shaft Fit and Alignment: It is essential to match the sprocket's bore and keyway to the shaft dimensions for proper installation and operation. Shafts support the sprockets, ensuring correct alignment and efficient power transmission throughout the conveyor system.

The Importance of Corrosion-Resistant Materials and Protective Coatings

One of the biggest challenges in marine applications is combating corrosion. Saltwater and humid environments accelerate metal degradation, leading to costly repairs and downtime. That’s why corrosion-resistant materials are essential:

- Stainless Steel: Highly resistant to rust and corrosion, stainless steel sprockets are a popular choice for marine use, offering longevity and strength.

- Alloy Steel with Protective Coatings: Specialised coatings such as powder coatings, zinc plating, or epoxy layers provide an additional barrier against corrosive elements.

- Composite Materials: For specific applications, lightweight composite sprockets offer corrosion resistance along with reduced weight, although they may have limitations in load capacity.

Using corrosion-resistant materials not only extends sprocket life but also reduces maintenance frequency and improves overall system reliability.

Installation and Maintenance Tips for Long-Lasting Sprocket Performance

Proper installation and ongoing maintenance are key to maximising the lifespan of

chain sprockets in demanding marine environments:

- Correct Alignment: Misalignment between sprockets and chains causes uneven wear and increases failure risks. Use precision tools to ensure proper alignment during installation.

- Lubrication: Regular lubrication with marine-grade lubricants prevents friction and wear, especially important where salt and moisture are present.

- Routine Inspections: Frequent checks for wear, corrosion, and chain tension help detect problems early before they cause system downtime.

- Timely Replacements: Replace sprockets showing significant tooth wear or deformation to avoid damaging the conveyor chain and other components.

At SLS, we recommend setting up a maintenance schedule tailored to your specific operational conditions to ensure continuous and trouble-free conveyor system operation.

Conclusion

Selecting the right chain sprocket for marine and shipyard conveyor systems is a critical decision that affects efficiency, reliability, and long-term operational costs. By considering load requirements, environmental challenges, material durability, and proper maintenance, you can optimise your conveyor’s performance and lifespan.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

Contact SLS for expert guidance and high-quality sprockets designed to withstand the toughest marine conditions.

Contact Us

Contact Us