In the food processing industry, pneumatic valves are essential for maintaining the highest hygiene and safety standards. They automate critical steps of production, help prevent contamination, and ensure consistent product quality. This article explores the importance of pneumatic valves in food processing, how they revolutionise production, their role in meeting safety regulations, and key maintenance practices to ensure optimal performance.

Understanding Pneumatic Valves and Their Importance in Food Processing

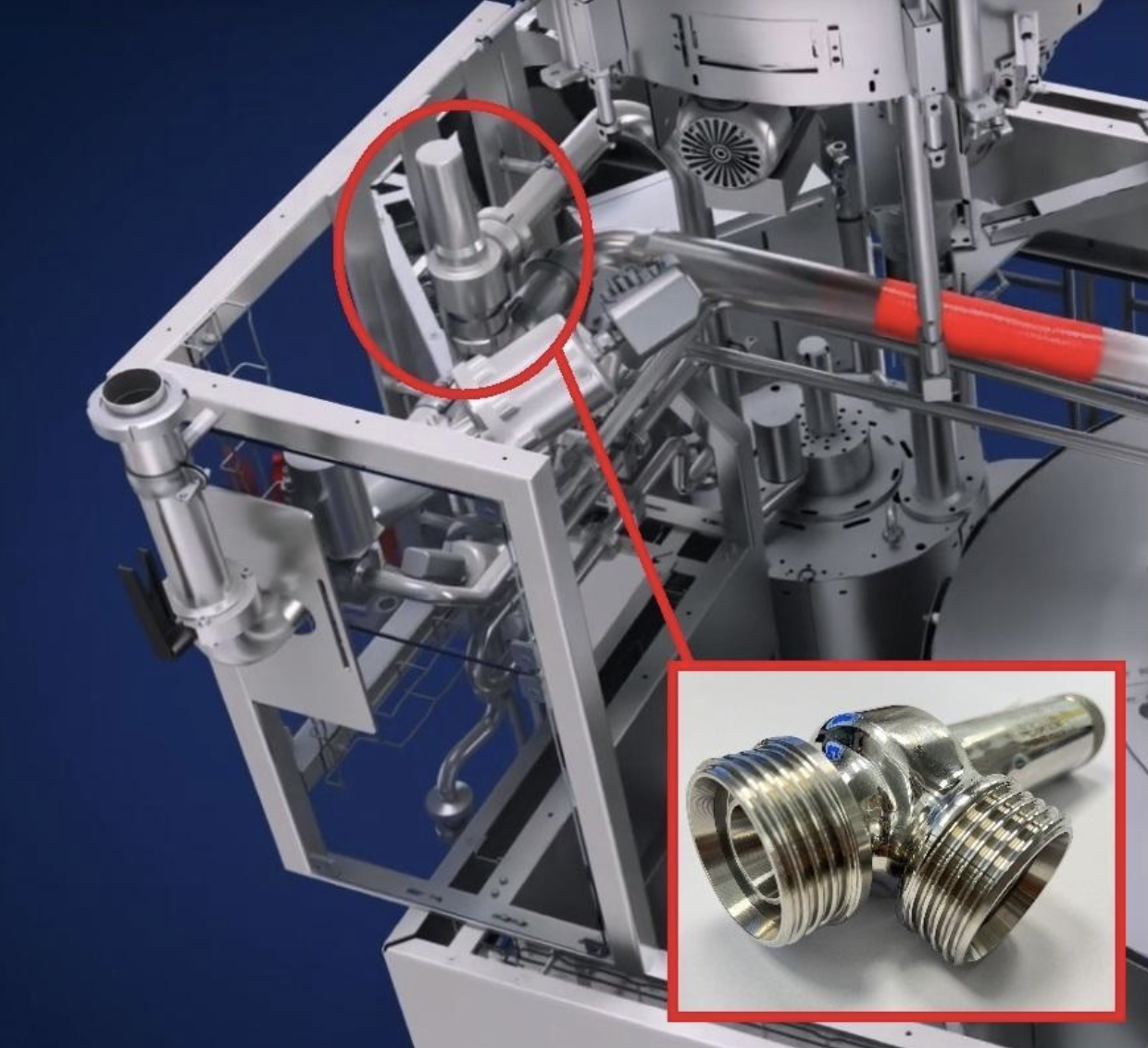

Pneumatic valves control the flow of liquids and gases through food manufacturing equipment using compressed air. Their design and materials are carefully chosen to meet the strict demands of the food industry and system requirements.

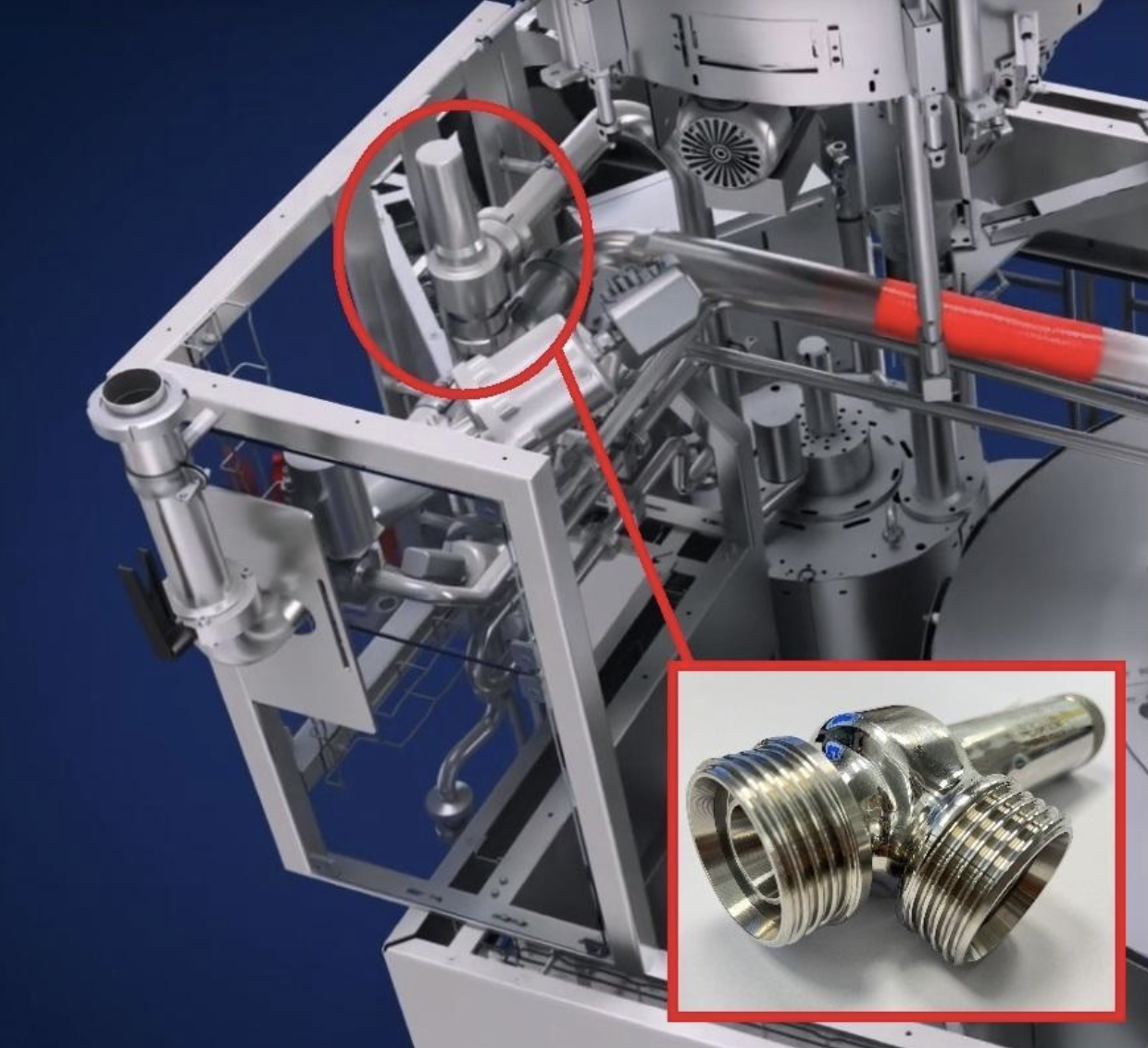

- Material Safety and Compatibility: Pneumatic valves for food processing are typically made from stainless steel, a corrosion-resistant and non-reactive material ideal for contact with food products. The seals are FDA-approved to ensure they don’t introduce contaminants, chemicals, or allergens into the product stream. This compatibility ensures that valves withstand harsh cleaning processes and aggressive food ingredients without degrading or compromising safety.

- Automation and Precision: Pneumatic valves provide precise and rapid control over processes such as filling, mixing, and packaging. This level of control is critical for ensuring that batches are consistent, which maintains product quality and reduces waste. Pneumatic valves enable manufacturers to scale production efficiently while meeting tight tolerances, reducing human error and improving throughout.

- Hygienic Design: These valves are engineered with smooth surfaces, minimal crevices, and easy-to-clean features to prevent bacteria or residue build-up. This hygienic design helps food producers maintain sanitary conditions throughout the processing line, which is vital for preventing contamination and complying with regulatory hygiene standards.

How Pneumatic Valves Are Transforming Food Production from Bottling to Packaging

The use of

pneumatic valves has transformed food production lines, enabling faster, more efficient, and safer processes from bottling to packaging.

- Enhanced Bottling Accuracy and Speed: In beverage and liquid food bottling lines, pneumatic valves ensure accurate portion control, adjusting quickly to changes in fluid viscosity and flow rates. This precision minimises overfills, spills, and waste, ultimately increasing productivity and reducing costs. The valves’ fast actuation supports high-speed filling lines without compromising accuracy.

- Seamless Packaging Integration: Pneumatic valves are integral to the smooth operation of packaging machinery, controlling conveyor belts, sealers, and capping devices. Their reliable and repeatable movements synchronise complex packaging steps, reducing downtime and manual intervention. This integration supports a range of packaging formats, allowing manufacturers to adapt to different product sizes and types rapidly.

- Smart Valve Technology: Advances in sensor integration and automation have led to “smart” pneumatic valves capable of remote monitoring and diagnostics. These valves provide real-time data on performance and wear, enabling predictive maintenance that reduces unexpected breakdowns. Such technology increases line uptime and ensures consistent product safety by detecting and addressing issues before failures occur.

The Role of A Pneumatic Valve in Meeting Safety and Hygiene Standards

Food safety is a top priority, and

pneumatic valves are designed to support stringent hygiene and regulatory requirements.

- Cleanability and Sterilisation: Pneumatic valves facilitate Clean-In-Place (CIP) and Sterilise-In-Place (SIP) processes, which clean and sterilise equipment without disassembly. Their smooth, polished surfaces and minimal internal dead zones prevent residue accumulation, making these procedures highly effective. This not only saves time but ensures thorough sanitation to prevent microbial growth.

- Regulatory Compliance: Valves in food production often carry certifications such as FDA, MOCA (Materials and Objects in Contact with Food), and ISO 22000. These certifications guarantee that all valve components in contact with food products meet strict safety standards, reducing the risk of chemical or physical contamination.

- Aseptic Operation: Pneumatic valves act as critical barriers preventing contamination during production. Their precise control helps maintain aseptic environments by minimising exposure to airborne particles and cross-contamination from equipment or operators. This is especially vital in sensitive processes such as dairy, juices, and ready-to-eat meals.

- Material Traceability and Quality: Many manufacturers provide full traceability of valve materials, such as 316L stainless steel, known for its durability and corrosion resistance. Traceability ensures transparency and confidence that materials used in valves are consistently safe and compliant with food safety standards.

Maintenance Tips to Ensure Pneumatic Valve Systems Operate Smoothly and Reliably

Proper maintenance of

pneumatic valves is crucial to prolong their system lifespan, maintain hygienic standards, and prevent costly downtime in food plants.

- Moisture Control: Food processing environments often have high moisture levels and temperature fluctuations that cause condensation inside pneumatic systems. This moisture can corrode valves and promote microbial growth. Installing moisture control devices such as drip legs, liquid separators, and dryers is essential to keep compressed air dry and protect pneumatic components.

- Use of Food-Grade Components: Always use solenoids, lubricants, and seals rated for food applications. For example, FDA-approved seals and food-grade lubricants reduce contamination risks and withstand cleaning chemicals used during CIP and SIP cycles.

- Routine Inspection and Cleaning: Regular inspection for wear, leaks, and residue build-up helps identify potential issues early. Cleaning valves can be used as part of the CIP process, removing residues that could harbor bacteria. Automated flushing via pneumatic actuators further enhances cleaning effectiveness without disassembling valves.

- Upgrade and Retrofit: Older systems might lack hygienic components. Retrofitting valves and actuators with corrosion-resistant and hygienic models improves system safety and reliability. Keeping up with evolving food safety standards by upgrading pneumatic components ensures continued compliance and operational efficiency.

- Professional Evaluation: Engage experts who specialise in pneumatic system maintenance within the food industry. They can audit your system’s trouble spots, recommend appropriate moisture control and hygienic valves, and tailor maintenance plans to your specific needs.

Pneumatic valves are indispensable in modern food processing, enabling automation, precision, and hygienic safety throughout the production cycle. Their carefully engineered materials and designs help food manufacturers meet strict safety regulations while enhancing productivity and product quality. By adopting best practices in maintenance and leveraging advanced valve technologies, food plants can ensure smooth, reliable operation that safeguards consumer health and trust. Investing in high-quality hygienic pneumatic valves ultimately supports the food industry’s mission to deliver safe, fresh, and high-quality products to the global market.

For those seeking professional assistance or specialised expertise in dealing with pneumatic valves, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

pneumatic valves selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us