In manufacturing industries, such as the semiconductor industry, the production process is filled with a wide range of machinery, all built and tuned to serve the demand of consumers. With countless of equipment at work, experiencing hiccups in the production process, such as wear and tear or misalignment in components, is inevitable. Thus, it becomes up to us to remain resilient in finding both production and maintenance solutions to ensure minimal downtime for excellent operational efficiency.

Misalignment can be a major risk and cost to production, making precision shaft alignment crucial to maintain machine reliability. Shaft alignment can help increase the operating life of mechanical components and reduce their wear, such as couplings and bearings. Let's discover how shaft alignment assists the semiconductor industry to ensure machines are maintained and our consumer demands are met.

What is Precision Shaft Alignment?

Shaft alignment is the critical process of precisely aligning two or more machine shafts that have become misaligned due to offset or angular discrepancies. There are two types of misalignments – angular and parallel misalignments.

Up to 50% of machinery breakdowns are due to misalignment. Some common causes of shaft misalignment are:

- Temperature: Changes in temperature or heat built up from friction can result in misalignment due to expansion.

- Human error: Improper engineering practices can result in issues during installation, such as shaft misalignment.

- Excess lubrication: Excess lubrication can cause increased wear and thus, an increased chance of misalignment.

Shaft misalignment results in increased wear and tear, vibration, and stress on couplings and bearings. This causes increased breakdowns, affecting the efficiency, safety, and reliability of equipment.

The Process of Semiconductor Manufacturing

Semiconductor manufacturing companies take these processing steps during production:

- Wafer Fabrication: The process of preparing the silicon wafer — cleaning it, and polishing it to be used as the base for the chips

- Photoresist Coating: Coating the silicon wafer in a light-sensitive chemical known as photoresist to harden it

- Photolithography: Projecting the circuit pattern with an ultraviolet light on the wafer, resulting in a chemical reaction

- Etch Processes: The photoresist is washed away to create the desired shape for the electrical components

- Deposition: Films with conducting, isolating, or semiconducting properties are added to the wafer

- Ion Implantation: Impurities are embedded in the silicon wafer to alter the electrical conducting properties in certain areas

- Packaging: The silicon wafer is cut into chips and assembled into a protective container that protects, keeps the chip cool, and directs signal output

This process is meticulously run hundreds of times before microchips are launched into the market. To keep up with the growth of the semiconductor industry, operations move constantly to sustain the demands, making them susceptible to misalignment issues.

The Importance of Precision Alignment in Semiconductor Manufacturing

Slight misalignments in equipment could result in mass failures in the semiconductor process. Machines involved in the wafer production or polishing process consist of many rotary parts, motors, and even pneumatic devices such as pressure sensors. Within these parts, components such as seals, bearings, and shafts benefit from precision alignment, as it helps increase component lifespan and avoid increased energy consumption, unwanted vibrations, and premature equipment failure.

Addressing misalignment helps to ensure semiconductor industry operations are precise and efficient, as errors in the semiconductor industry can be consequential to production and lead to failure to meet demand or faulty microchips.

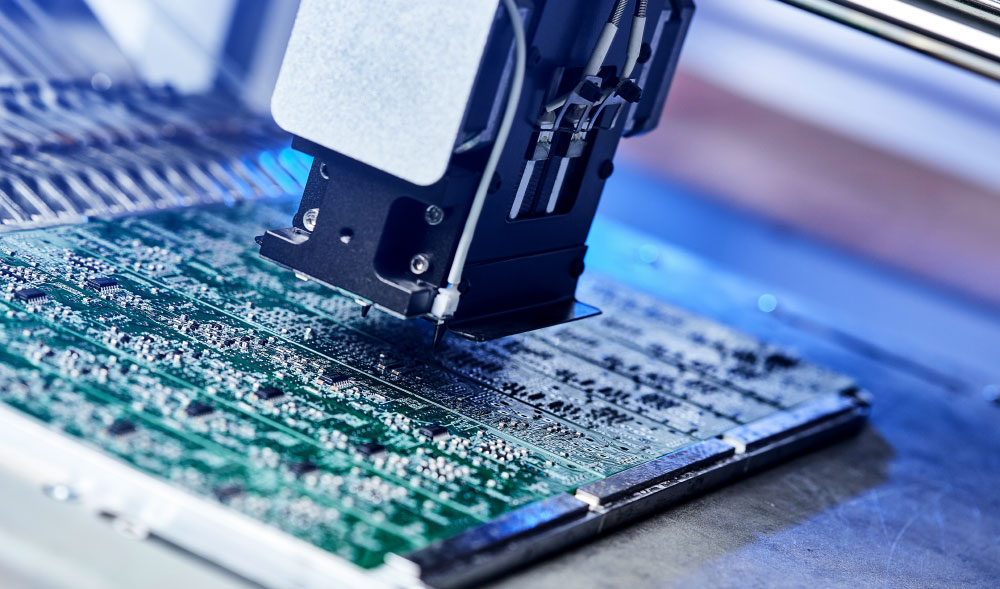

How Robotic Automation Affects the Semiconductor Industry

Robotic automation is commonly used to automate repeatitive processes in industries with calculated precision. Accuracy, speed, and efficiency are crucial to semiconductor device manufacturing, which makes robotic automation a vital and essential investment.

These robots take on the tasks to assemble and test the microchips, each equipped with automated systems such as the Automated Optical Inspection (AOI) system that inspects for chip defects.

Shaft alignment, likewise, is also supported with the power of robotic automation. Laser alignment tools are an example where automation is used to execute alignment tasks, maintaining rotary machinery and providing precise measurements. These tools are designed for maintenance purposes, quickly calculating and performing precision shaft alignments on misaligned components.

Conclusion

Semiconductors are part of our day-to-day life. Every chip holds value, and every component is crucial. In the demanding semiconductor device manufacturing industry landscape, efficiency, precision, and quality are crucial for ensuring the proper functioning of devices, which is why you

cannot risk misalignment in your manufacturing equipment.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

Contact SLS for expert guidance on precision shaft alignment services and discover how we maintain and support your operations.

Contact Us

Contact Us